MBD model quality inspection and management

- MBDVidia software - CAD model format conversion + 3D model PMI annotation checking and management + importing measurement results into 3D models + automatically generating FAI and other reports

- MBD model quality management function plugin of CAD system - real MBD model + CAD model format conversion + automatic generation of 2D drawing bubble diagram + PMI human-readable + measurement result import into MBD model + automatic generation of FAI report

- CompareVidia Software - CAD Model Data Conversion and Verification Software ++ Automatically generates customizable reports + Complies with Boeing D6-51991 standards + CAD model file version management + 3D PMI annotation management

- Pundit Software - Intelligent CMM Detection Simulation Software + Optimized Measurement Plan + Measurement Plan Uncertainty Analysis + Simulated Detection Process + Finding Defects in GD&T

CAD Modeling and Repair

CAE Simulation Analysis

Environmental Stress Excitation Testing

- HAMT High Acceleration Maturity Test System - Improve Product Quality, Enhance Operational Efficiency, Accelerate Product Market Launch

- American HANSE Special Environment Test Chamber - Highly Accelerated Life Testing and Product Reliability Testing

- Electromagnetic Vibration Test System - Conducting product failure analysis through sinusoidal vibration, random vibration, and classical impact tests.

- Impact Testing Machine - Correction of Support Structure and Analysis of Material Properties

- Drop Test Machine - Product Structure Verification and Reliability Analysis

Vibration and Displacement Strain Measurement

- EikoTwin FE-DIC 3D Full-Field Non-Contact Optical Strain Measurement System

- HoloBright Laser Doppler Multi-Point Vibration Meter - Long-Distance Laser Vibration Measurement Equipment

- PMLAB DIC-3D Pro Traditional DIC Strain Measurement System - Full-field Non-contact Strain Measurement

- SP-SWI/SP-DWI Optical Static/Dynamic Surface Profilometer - Dynamic/Static Morphology Measurement + Resonant Frequency Detection

Sound and Vibration Measurement

- Signal-Wise Comprehensive Noise Diagnosis and Analysis System - Noise Source Localization + 3D Sound Field Reconstruction

- Signal-Wise X-tractor Intelligent Signal Recognition Quality Inspection Analysis System - Product QC Testing + Designated Defect Recognition

- SoundPLAN Noise Prediction Assessment Tool - Outdoor Noise Detection and Assessment Software

- SonoCat multifunctional acoustic measurement device - on-site sound source location, detection of sound pressure & sound intensity & material surface sound absorption effect parameters.

- Norsonic Far-field Sound and Vibration Measurement System - Noise Analysis + Noise Source Identification and Localization

- Synave Near-field 3D Acoustic Holography Measurement System - 3D Sound Field Reconstruction + Noise Source Localization

- Visual Signal Sound Signal Analysis Tool - Vibration Noise Signal Visualization

- COCO80/90 Dynamic Signal Analyzer - Handheld Noise Signal Recording and Analysis Device

Biomechanical Analysis

- BOB Human Muscle and Skeletal Simulation Modeling Software - Biomechanical Analysis of Movement

- BTS Biomechanical Motion Analysis System - Human Motion Data Collection Equipment

- PRO-GRF Ground Reaction Force Professional Analysis System

- SPI-Tactilus Foot Pressure Testing System - Real-time Contact Surface Pressure Analysis

- Vehicle Seat Comfort Measurement System - CASIMIR and MEMOSIK

SPI Surface Pressure Full-Field Measurement System

- SPI-FreeForm® Real-time Contact Pressure Testing System - Automotive Door Sealing Test - 1

- SPI-FreeForm® Real-time Contact Pressure Testing System - Automotive Door Sealing Test - 2

- SPI-Tactilus® Surface Contact Pressure Analysis System

- SPI-Tactilus® Flex Bending Degree Measurement Sensor

- SPI-Tactilus® Real-time Contact Pressure Measurement System (Heat Exchange Applications)

- SPI-Tactilus® Real-time Contact Pressure Measurement System - Pressure Indicating Washer

- SPI-Tactilus® Real-time Contact Pressure Testing System - Application in Heat Dissipation Equipment

- SPI-Pressures-micro®Green contact pressure indicating pressure-sensitive paper / pressure-sensitive film

- SPI-Tactilus Free From® Real-time Contact Pressure Testing System - Appliance Door Sealing Test

Non-destructive testing

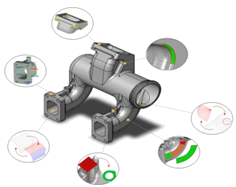

3DTransVidia - CAD Model Format Conversion and Repair Software

3DTransVidia is a powerful 3D model format conversion and repair software that can perform 3D model format conversion and model repair in all 3D CAD/CAM/CAE systems, making the transmission and transformation of 3D model data between enterprises and between upstream and downstream software smoother. 3DTransVidia supports file formats such as Pro/E, UG, CATIA V4, CATIA V5, SolidWorks, STL, STEP, IGES, Inventor, ACIS, VRML, AutoForm, Parasolid, etc.

The 3DTransVidia software mainly has three major functions:

1. Format conversion - Achieve mutual conversion between mainstream 3D CAD model formats.

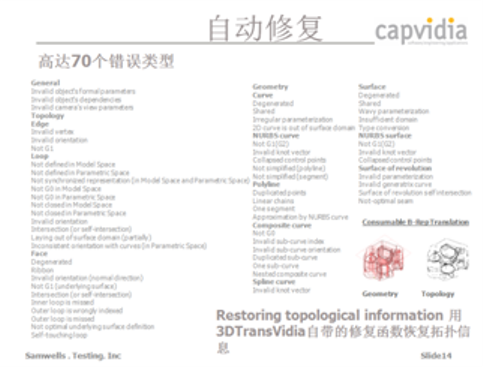

2. Model repair - 3DTransVidia has powerful automatic repair and human-computer interactive model repair functions, capable of automatically repairing over 70 types of errors.

3. Quality improvement - Ensure that 3D models meet certain industry international standards or custom standards, satisfying engineering processing quality precision.

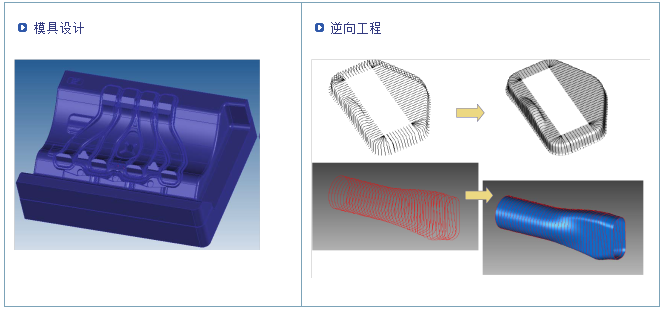

3DTransVidia also provides special function modules such as reverse engineering, offset, feature transformation, and mesh editing.

Typical customers of 3DTransVidia software include: BOEING, Mercedes-Benz,

HONDA, TOYOTA, and other international enterprises.

Functions:

1. Format conversion. Achieve mutual conversion between mainstream 3D CAD model formats.

2. Model repair. 3DTransVidia has powerful automatic repair and human-computer interactive model repair functions, capable of automatically repairing over 70 types of errors.

3. Quality improvement. Ensure that 3D models meet certain industry international standards or custom standards, satisfying engineering processing quality precision. 3DTransVidia also providesspecial function modules such as reverse engineering, offset, feature transformation, and mesh editing.

System features:

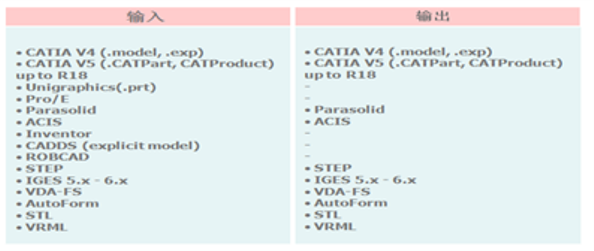

1. Complete input and output formats - model conversion capability.

In terms of data input interfaces, 3DTransVidia can almost directly read the proprietary formats of commonly used CAD systems on the market, such as CATIA (V4/V5), Unigraphics (.prt), Pro/E, Inventor, Parasolid, etc. Of course, it fully supports general CAD model formats, such as STEP, IGES, STL, VRML, etc. In terms of data output interfaces, 3DTransVidia fully supports CATIA (V4/V5) and Parasolid-based CAD systems, and can smoothly output general formats.

2. Automatic classification and repair of model error types.

3DTransVidia provides a comprehensive model error repair function, capable of detecting and repairing various model error issues caused by topological or geometric information conflicts.3. Rich manual recovery functions.

4. Unique features.

Surface simplification.

Advanced surface approximation processing.

Reverse engineering.

Shell replacement.

Shell offset.

Surface deformation.

Mesh repair tools.

Surface fitting (transfer from Catia V4 to Catia V5).

Feature transfer (Catia V5 -> SolidWorks -> Catia V5).

Applications:

File conversion, repair, and quality inspection of automotive parts.

Customers:

HONDA, Audi, Intel, Philips, Alcatel, AutoForm, ABB, Boeing, Toshiba, ICOS Vision, InBev, Electrabel, Tyco, Atlas Copco, Goodyear, Toyota, Nissan, NASA, OnoSokki, StoraEnso, ....

HONDA、Audi、Intel, Philips, Alcatel, AutoForm, ABB, Boeing, Toshiba,ICOS Vision, InBev, Electrabel, Tyco, Atlas Copco, Goodyear,Toyota, Nissan, NASA, OnoSokki, StoraEnso, ….