MBD model quality inspection and management

- MBDVidia software - CAD model format conversion + 3D model PMI annotation checking and management + importing measurement results into 3D models + automatically generating FAI and other reports

- MBD model quality management function plugin of CAD system - real MBD model + CAD model format conversion + automatic generation of 2D drawing bubble diagram + PMI human-readable + measurement result import into MBD model + automatic generation of FAI report

- CompareVidia Software - CAD Model Data Conversion and Verification Software ++ Automatically generates customizable reports + Complies with Boeing D6-51991 standards + CAD model file version management + 3D PMI annotation management

- Pundit Software - Intelligent CMM Detection Simulation Software + Optimized Measurement Plan + Measurement Plan Uncertainty Analysis + Simulated Detection Process + Finding Defects in GD&T

CAD Modeling and Repair

CAE Simulation Analysis

Environmental Stress Excitation Testing

- HAMT High Acceleration Maturity Test System - Improve Product Quality, Enhance Operational Efficiency, Accelerate Product Market Launch

- American HANSE Special Environment Test Chamber - Highly Accelerated Life Testing and Product Reliability Testing

- Electromagnetic Vibration Test System - Conducting product failure analysis through sinusoidal vibration, random vibration, and classical impact tests.

- Impact Testing Machine - Correction of Support Structure and Analysis of Material Properties

- Drop Test Machine - Product Structure Verification and Reliability Analysis

Vibration and Displacement Strain Measurement

- EikoTwin FE-DIC 3D Full-Field Non-Contact Optical Strain Measurement System

- HoloBright Laser Doppler Multi-Point Vibration Meter - Long-Distance Laser Vibration Measurement Equipment

- PMLAB DIC-3D Pro Traditional DIC Strain Measurement System - Full-field Non-contact Strain Measurement

- SP-SWI/SP-DWI Optical Static/Dynamic Surface Profilometer - Dynamic/Static Morphology Measurement + Resonant Frequency Detection

Sound and Vibration Measurement

- Signal-Wise Comprehensive Noise Diagnosis and Analysis System - Noise Source Localization + 3D Sound Field Reconstruction

- Signal-Wise X-tractor Intelligent Signal Recognition Quality Inspection Analysis System - Product QC Testing + Designated Defect Recognition

- SoundPLAN Noise Prediction Assessment Tool - Outdoor Noise Detection and Assessment Software

- SonoCat multifunctional acoustic measurement device - on-site sound source location, detection of sound pressure & sound intensity & material surface sound absorption effect parameters.

- Norsonic Far-field Sound and Vibration Measurement System - Noise Analysis + Noise Source Identification and Localization

- Synave Near-field 3D Acoustic Holography Measurement System - 3D Sound Field Reconstruction + Noise Source Localization

- Visual Signal Sound Signal Analysis Tool - Vibration Noise Signal Visualization

- COCO80/90 Dynamic Signal Analyzer - Handheld Noise Signal Recording and Analysis Device

Biomechanical Analysis

- BOB Human Muscle and Skeletal Simulation Modeling Software - Biomechanical Analysis of Movement

- BTS Biomechanical Motion Analysis System - Human Motion Data Collection Equipment

- PRO-GRF Ground Reaction Force Professional Analysis System

- SPI-Tactilus Foot Pressure Testing System - Real-time Contact Surface Pressure Analysis

- Vehicle Seat Comfort Measurement System - CASIMIR and MEMOSIK

SPI Surface Pressure Full-Field Measurement System

- SPI-FreeForm® Real-time Contact Pressure Testing System - Automotive Door Sealing Test - 1

- SPI-FreeForm® Real-time Contact Pressure Testing System - Automotive Door Sealing Test - 2

- SPI-Tactilus® Surface Contact Pressure Analysis System

- SPI-Tactilus® Flex Bending Degree Measurement Sensor

- SPI-Tactilus® Real-time Contact Pressure Measurement System (Heat Exchange Applications)

- SPI-Tactilus® Real-time Contact Pressure Measurement System - Pressure Indicating Washer

- SPI-Tactilus® Real-time Contact Pressure Testing System - Application in Heat Dissipation Equipment

- SPI-Pressures-micro®Green contact pressure indicating pressure-sensitive paper / pressure-sensitive film

- SPI-Tactilus Free From® Real-time Contact Pressure Testing System - Appliance Door Sealing Test

Non-destructive testing

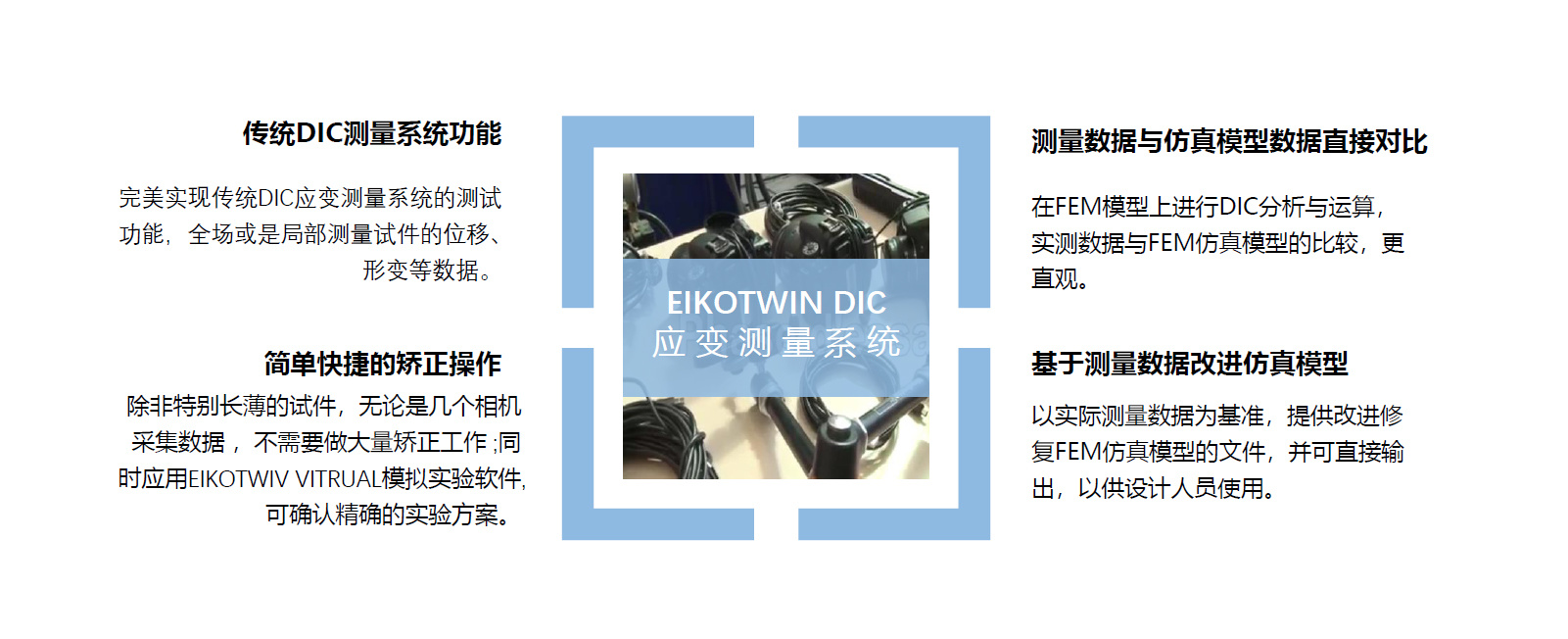

EikoTwin FE-DIC 3D Full-Field Non-Contact Optical Strain Measurement System

(EikoSim DIC Strain Measurement System Product Introduction CatalogDownload, Baidu Cloud download extraction code: 9xbw)

(Click the image to watch the EikoSim DIC Strain Measurement System introduction video)

System Introduction:

The EikoSim DIC Strain Measurement System is a highly contactless 3D full-field optical strain analysis system introduced by Beijing Qiaoze in 2020, consisting of hardware such as computers and cameras, and the EikoTwin software analysis system. This system has made many improvements based on traditional DIC measurement systems, performing digital image correlation processing based on FEM simulation models, allowing for direct comparison of FEM simulation data and measured strain data on the same platform. The provider of this system, EikoSim, is a software startup company in France, whose CEO FLORENT MATHIEU and Chief Technology Officer Renaud Gras are both PhDs in mechanics. From 2009 to 2015, they worked with Pr. Hild and Pr. Roux at the renowned European mechanics laboratory "LMT Cachan," jointly committed to the research and development of DIC measurement technology (Pr. Hild and Pr. Roux are leading figures in DIC strain measurement technology in the mechanical industry). After EikoSim was established in France in 2016, FLORENT MATHIEU and Renaud Gras led their entire team to actively explore and practice in the application of DIC measurement technology. As a result, EikoSim's DIC products incorporate relatively advanced DIC technology measurement solutions. For example, the results of analyzing displacement, strain, and other data collected through DIC software can be directly compared with FEM simulation models without gaps, and even the FEM simulation model can be repaired and improved based on experimental data, making users' work faster and more effective, reducing the number of experiments conducted in reality, and ensuring or completing work goals ahead of schedule. Currently, EikoSim's DIC strain measurement system is favored by users in industries such as aerospace, defense, automotive, and research institutions abroad, such as ARIANE GROUP (Arianespace in France), AIR BUS (Airbus in Europe), SAFRAN (Safran Group in France), and CETIM (French Mechanical Industry Technology Center), all of which are loyal users of EikoSim's DIC strain measurement system.

EikoTwin-DIC Optical Full-Field Measurement Solution:

* Image processing based on finite element mesh

* Automatic calibration around the mesh

* Multi-view (no technical limit on the number of cameras)

The EikoTwin DIC software system requires image files and FEM model files in a matching format, such as:

1) Format for importing images taken by visible light cameras: .tif, .png, .jpg, .bmp

2) Format for importing infrared camera images: .mat(-v.4)

3) Imported MESH model formats:

▪ Abaqus format (.inp): compatible with any type of linear and nonlinear elements and all element type formats (from version 2018 onwards)

▪ Samcef format (.dat): compatible with Tri/Tetra, Quad/Hex, and Wedge types of linear and nonlinear elements, as well as the following format

written in "AEL" type: "I element number FRAME local landmark number"

▪ Gmsh format (.msh): compatible with any version up to 4.1, except 4.0

▪ HyperWorks format (.h3d)

Beijing Qiaoze Strain Measurement Products and Services: 010-65610249, 021-52522440

Contact Person: Manager Cheng, 17317384736

E-mail:info@deanwell.com.cn

Click here to learn about product strain measurement consulting services.

Application Cases:

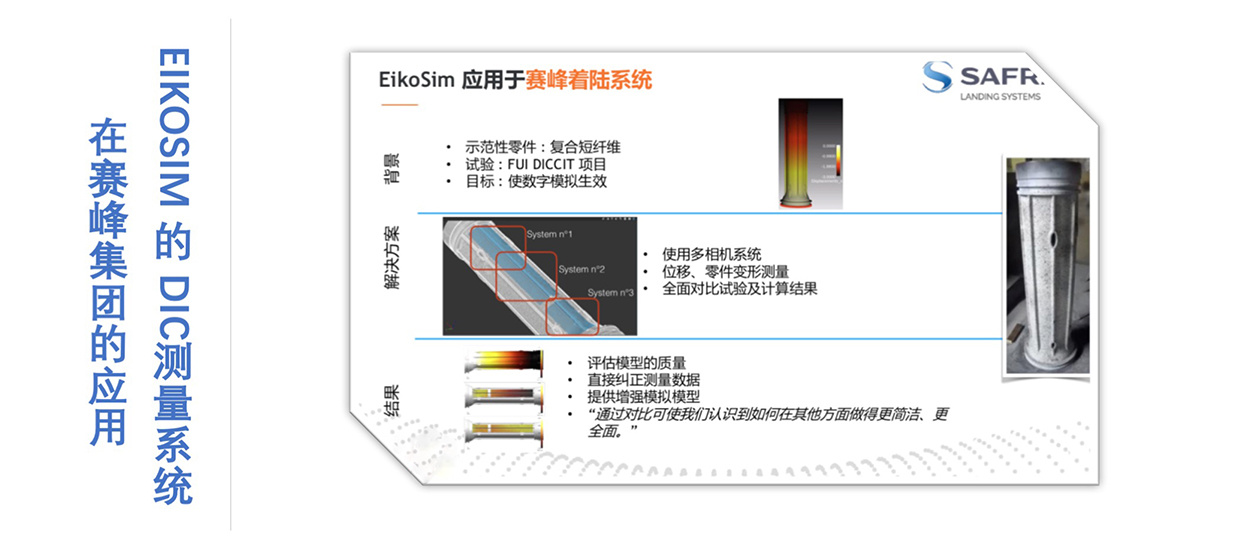

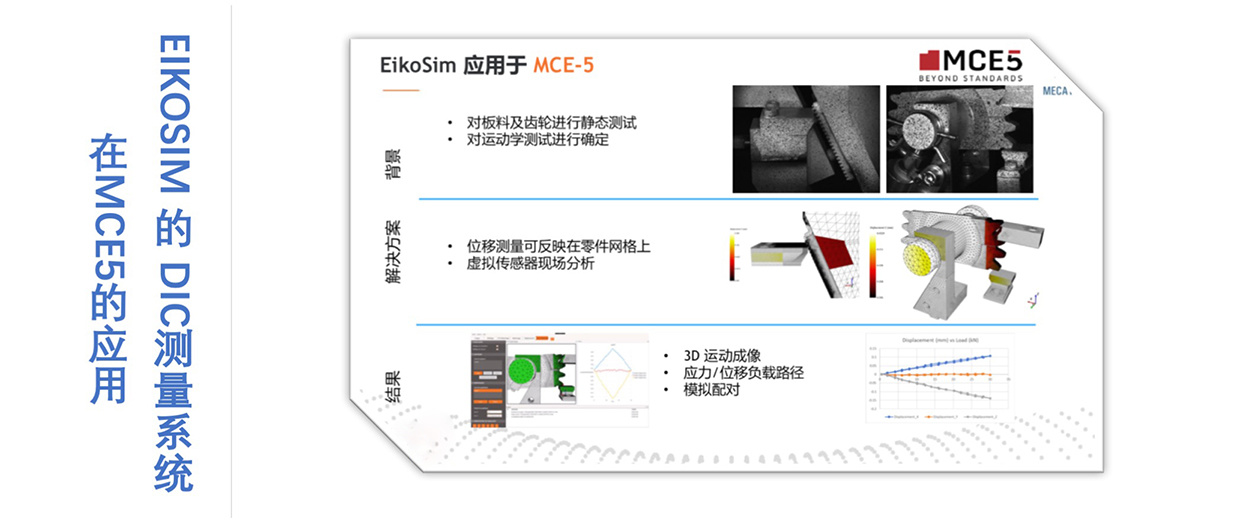

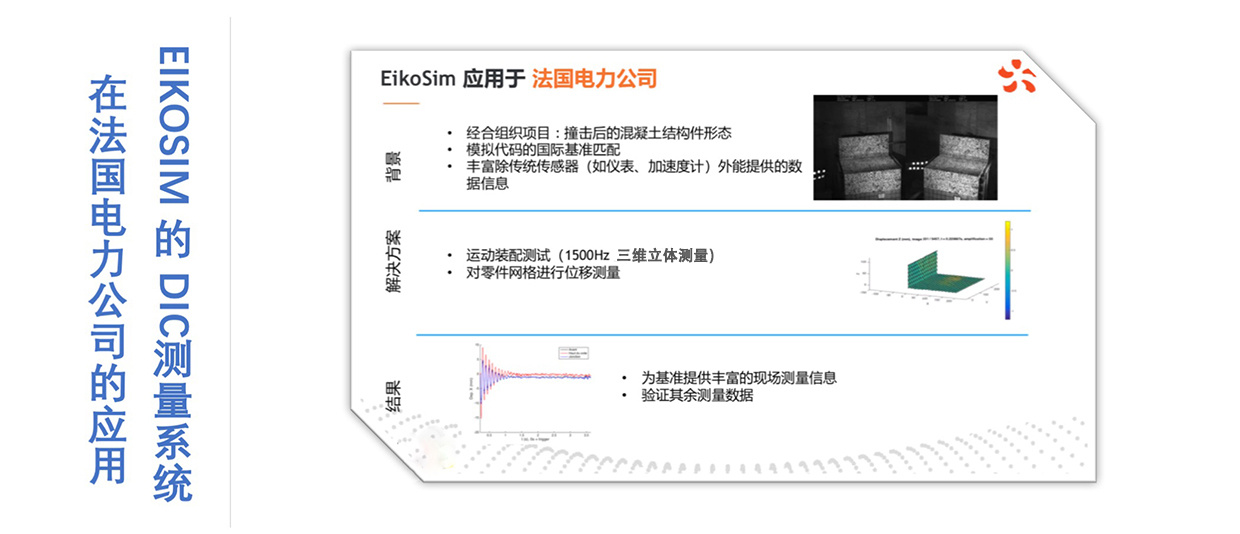

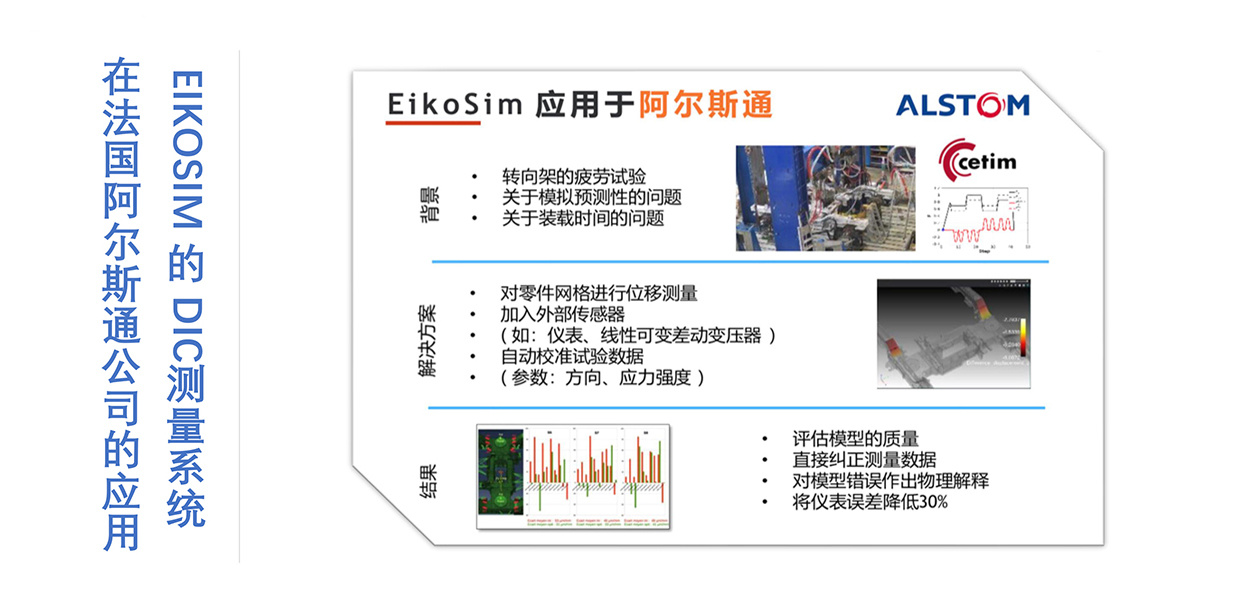

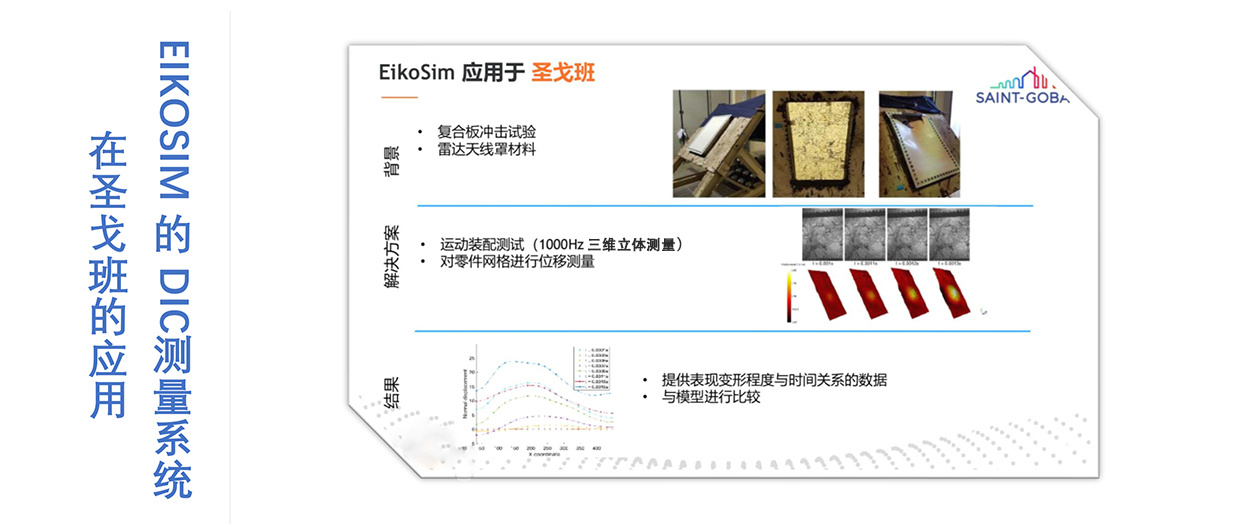

Application of EikoSim Virtual-Real Integration Technology Worldwide: