MBD model quality inspection and management

- MBDVidia software - CAD model format conversion + 3D model PMI annotation checking and management + importing measurement results into 3D models + automatically generating FAI and other reports

- MBD model quality management function plugin of CAD system - real MBD model + CAD model format conversion + automatic generation of 2D drawing bubble diagram + PMI human-readable + measurement result import into MBD model + automatic generation of FAI report

- CompareVidia Software - CAD Model Data Conversion and Verification Software ++ Automatically generates customizable reports + Complies with Boeing D6-51991 standards + CAD model file version management + 3D PMI annotation management

- Pundit Software - Intelligent CMM Detection Simulation Software + Optimized Measurement Plan + Measurement Plan Uncertainty Analysis + Simulated Detection Process + Finding Defects in GD&T

CAD Modeling and Repair

CAE Simulation Analysis

Environmental Stress Excitation Testing

- HAMT High Acceleration Maturity Test System - Improve Product Quality, Enhance Operational Efficiency, Accelerate Product Market Launch

- American HANSE Special Environment Test Chamber - Highly Accelerated Life Testing and Product Reliability Testing

- Electromagnetic Vibration Test System - Conducting product failure analysis through sinusoidal vibration, random vibration, and classical impact tests.

- Impact Testing Machine - Correction of Support Structure and Analysis of Material Properties

- Drop Test Machine - Product Structure Verification and Reliability Analysis

Vibration and Displacement Strain Measurement

- EikoTwin FE-DIC 3D Full-Field Non-Contact Optical Strain Measurement System

- HoloBright Laser Doppler Multi-Point Vibration Meter - Long-Distance Laser Vibration Measurement Equipment

- PMLAB DIC-3D Pro Traditional DIC Strain Measurement System - Full-field Non-contact Strain Measurement

- SP-SWI/SP-DWI Optical Static/Dynamic Surface Profilometer - Dynamic/Static Morphology Measurement + Resonant Frequency Detection

Sound and Vibration Measurement

- Signal-Wise Comprehensive Noise Diagnosis and Analysis System - Noise Source Localization + 3D Sound Field Reconstruction

- Signal-Wise X-tractor Intelligent Signal Recognition Quality Inspection Analysis System - Product QC Testing + Designated Defect Recognition

- SoundPLAN Noise Prediction Assessment Tool - Outdoor Noise Detection and Assessment Software

- SonoCat multifunctional acoustic measurement device - on-site sound source location, detection of sound pressure & sound intensity & material surface sound absorption effect parameters.

- Norsonic Far-field Sound and Vibration Measurement System - Noise Analysis + Noise Source Identification and Localization

- Synave Near-field 3D Acoustic Holography Measurement System - 3D Sound Field Reconstruction + Noise Source Localization

- Visual Signal Sound Signal Analysis Tool - Vibration Noise Signal Visualization

- COCO80/90 Dynamic Signal Analyzer - Handheld Noise Signal Recording and Analysis Device

Biomechanical Analysis

- BOB Human Muscle and Skeletal Simulation Modeling Software - Biomechanical Analysis of Movement

- BTS Biomechanical Motion Analysis System - Human Motion Data Collection Equipment

- PRO-GRF Ground Reaction Force Professional Analysis System

- SPI-Tactilus Foot Pressure Testing System - Real-time Contact Surface Pressure Analysis

- Vehicle Seat Comfort Measurement System - CASIMIR and MEMOSIK

SPI Surface Pressure Full-Field Measurement System

- SPI-FreeForm® Real-time Contact Pressure Testing System - Automotive Door Sealing Test - 1

- SPI-FreeForm® Real-time Contact Pressure Testing System - Automotive Door Sealing Test - 2

- SPI-Tactilus® Surface Contact Pressure Analysis System

- SPI-Tactilus® Flex Bending Degree Measurement Sensor

- SPI-Tactilus® Real-time Contact Pressure Measurement System (Heat Exchange Applications)

- SPI-Tactilus® Real-time Contact Pressure Measurement System - Pressure Indicating Washer

- SPI-Tactilus® Real-time Contact Pressure Testing System - Application in Heat Dissipation Equipment

- SPI-Pressures-micro®Green contact pressure indicating pressure-sensitive paper / pressure-sensitive film

- SPI-Tactilus Free From® Real-time Contact Pressure Testing System - Appliance Door Sealing Test

Non-destructive testing

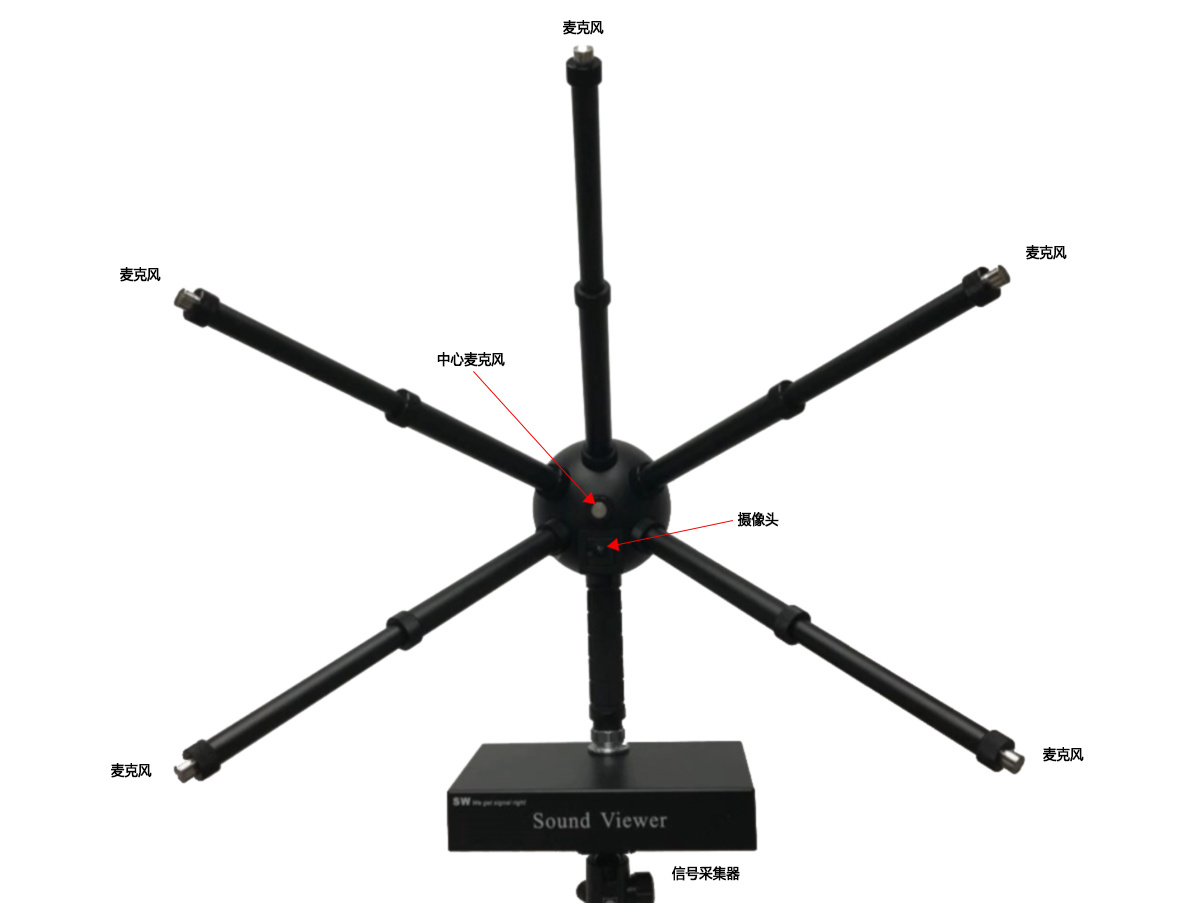

Signal-Wise Comprehensive Noise Diagnosis and Analysis System - Noise Source Localization + 3D Sound Field Reconstruction

The Vision Sound Instrument is a comprehensive noise detection and analysis system launched by the American company Signal-Wise. Since the development of the first generation in 2015, it has undergone several updates and finally completed the 6.0 version system in 2021. The Vision Sound Instrument is suitable for detecting and analyzing almost all air sound, structural sound, and aerodynamic noise in engineering applications, as well as sound source localization.

Hardware Composition

The hardware of the Vision Sound Instrument mainly consists of a 3D microphone array with microphone tubes and an eight-channel data acquisition unit. By using a 3D array, users will be able to accurately locate multiple sound sources in 3D space simultaneously, including their ranges. The use of extendable microphone tubes allows the system to handle various noise issues, especially in situations where the measurement space is relatively limited, such as inside a car passenger cabin.

Six channels are designated for microphone measurements. The remaining two channels are used for reference signals, such as tachometer readings during order tracking analysis on any rotating axis, or input power signals during STL (Sound Transmission Loss) analysis.

Basic Principles

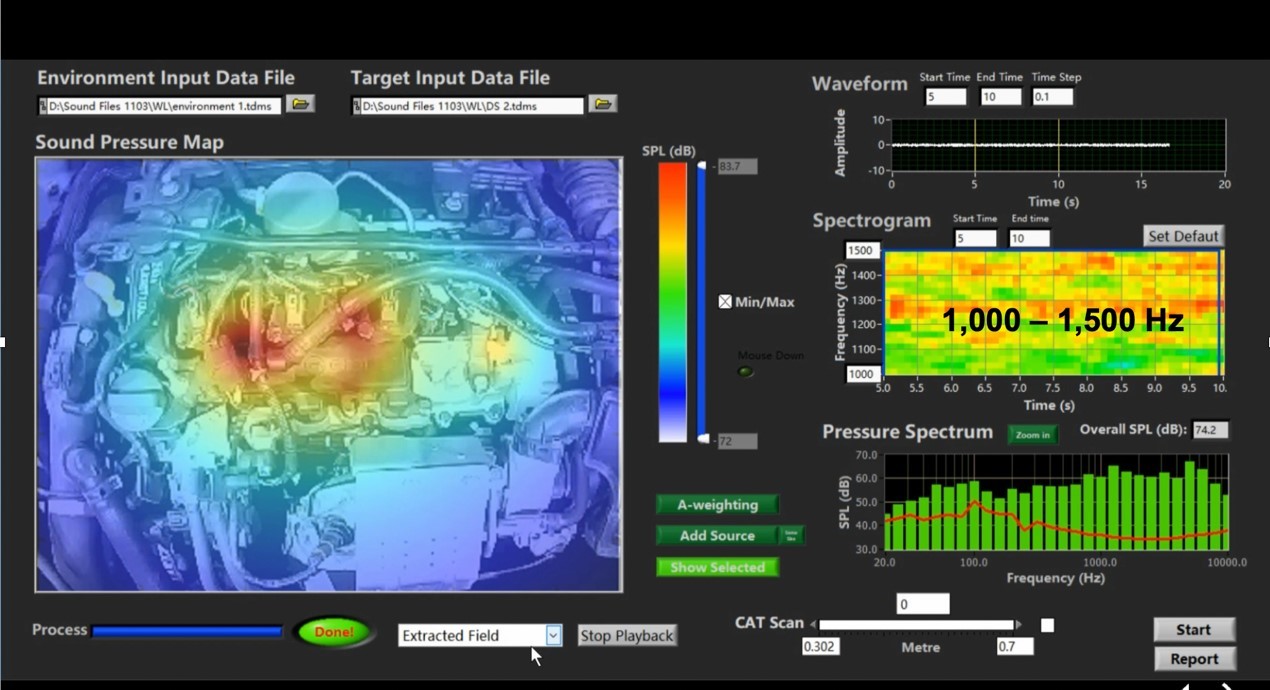

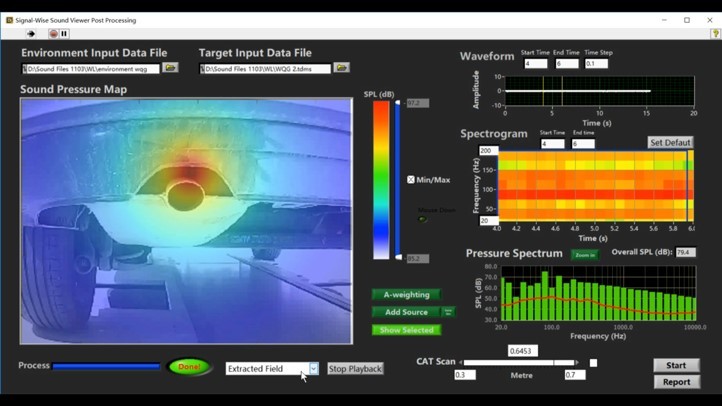

The Vision Sound Instrument is a disruptive product based on intelligent sound arrival theory and the least squares method of the Helmholtz equation. In simple terms, the intelligent sound arrival theory uses intelligent statistical optimization triangulation principles to determine the position of any sound source in three-dimensional space; the least squares method of the Helmholtz equation reconstructs the optimal sound field distribution based on the input sound signal.The combination of the two forms rake noise control technology, allowing the Vision Sound Instrument to enable users to detect and analyze any complex noise sources and the three-dimensional sound fields they generate.

Product Features

Before the Vision Sound Instrument, common noise detection and analysis tools on the market could only provide a certain physical quantity at a measurement point, such as the sound pressure level given by a microphone or the sound intensity level given by a sound intensity meter. These traditional measurement methods could not provide a global concept, especially failing to obtain all acoustic physical quantities on any structural surface. Meanwhile, traditional measurement methods could only determine the azimuth angle of the sound source, without being able to determine the longitudinal distance to the sound source.

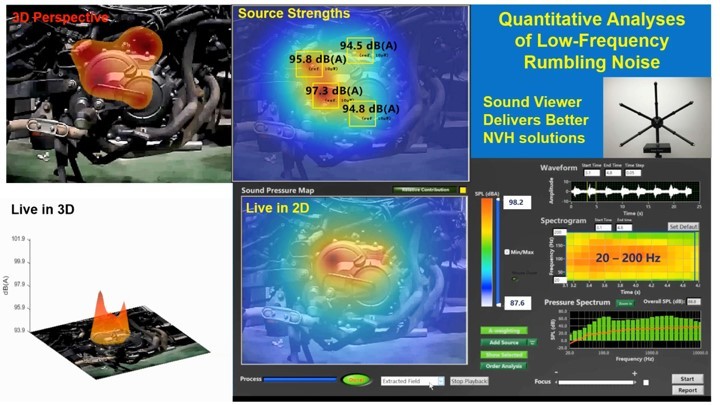

In addition to being able to simultaneously determine the positions of multiple sound sources in three-dimensional space, namely the azimuth angle and longitudinal distance, the Vision Sound Instrument can also provide the distribution of all acoustic physical quantities on any shaped structural surface and within three-dimensional space, analyze the sound transmission of any materials and structures, or plates, and analyze the sound radiation of transmission components during changes in rotational speed. The frequency band and dynamic range detected, analyzed, and displayed by the Vision Sound Instrument are consistent with those of the measurement microphone; the wider the microphone's frequency band and the larger its dynamic range, the wider the frequency band range and the larger the dynamic range displayed in real-time by the Vision Sound Instrument. For example, if the microphone's frequency band is 20Hz - 20KHz and the dynamic range is 140dB, the results detected and analyzed by the Vision Sound Instrument will also be 20Hz - 20KHz and 140dB. The spatial resolution of sound sources by the Vision Sound Instrument is independent of the frequency of sound waves.

Application Fields

The Vision Sound Instrument is suitable for detecting and analyzing almost all air sound, structural sound, and startup noise, and obtaining the distribution of all acoustic physical quantities in any three-dimensional space: such as sound pressure level distribution, sound pressure spectrum, sound intensity level distribution, sound intensity spectrum, sound power level, sound power spectrum, etc., on any structural surface and within three-dimensional space. The Vision Sound Instrument has been used for low-frequency noise analysis of motorcycles under steady-state and transient conditions, identification of low-frequency low signal-to-noise ratio automobile noise sources, product quality inspection on production lines, analysis of product defects on production lines, etc. For the above applications, Professor Sean Wu, the main technical founder of Signal-Wise Vision Sound Instrument, led his students to present related articles at the American Noise and Vibration Conference & Exhibition.

2)Identification of Low-Frequency/Low SNR Automobile Noise Sources

(Engine noise source localization)

(Analysis of low-frequency rumble noise of motorcycles)

(Automobile tailpipe noise localization and analysis)

Partial Client References