|

|

|

Original introduction:

The highly accelerated life test system represented by Beijing Qiaoze Technology Co., Ltd. is a device manufactured by HANSE in the United States.

With more than 20 years of experience in R&D and practice, HANSE is now a leading supplier of vibration systems in the world, including HAL T&HASS, ESS, special environmental chambers, individual chambers and six-degree-of-freedom vibration systems, and has now introduced a 100Grms vibration system, which puts HANSE once again ahead of all its competitors.

Product Description:

R&D designers continuously improve the defects exposed by the products in the HALT&HASS test, and ultimately achieve the improvement of product quality and longevity.

Highly Accelerated Life Test (HALT)

HALT test is used in the design and development stage of products, by imposing increasing environmental stress on the product to find out the use limit and damage limit of the product, exposing various inherent defects and weak points of the product, and the design and development personnel can improve the reliability and life of the product by analyzing and improving the defects and weak points exposed in the HALT test.

Highly Accelerated Stress Screening (HASS)

Referring to the results obtained from the HALT test can establish a very effective HASS screening procedure, which should be applied to all products to ensure their reliability and validity.

Function Description:

There are nine benefits of HALT:

♦ Quickly find out the defects in the product process (quickly find out the defects within 3~5 days)

♦ The growth of the manufacturing process accelerates the maturity of design and manufacturing (after giving incentives and failing, modify the design to accelerate the maturity of design and manufacturing);

♦ Shorter time-to-market and faster time-to-market (shorter trial time);

♦ Improved MTBF (Mean Time to Failure Growth);

♦ Extended warranty;

♦ Reduced warranty costs (reduced recycling and repair costs);

♦ early availability of data on product strength (means of improving product strength);

♦ Reduce costs (shorten product development time, cost);

♦ Customers use highly reliable products

(Solve design defects before listing, improve customer satisfaction, improve the good quality image of the company's products, and increase market share).

HALT technology is designed to increase reliability in the shortest time and with the least cost to produce world-class quality products, and to establish an environmental stress screening HASS classification for mass production processes.

System Features:

Temperature:

- Temperature range: -100°C - +200°C

- The temperature change rate can reach 70°C/min

- Temperature control stability up to ±1°C

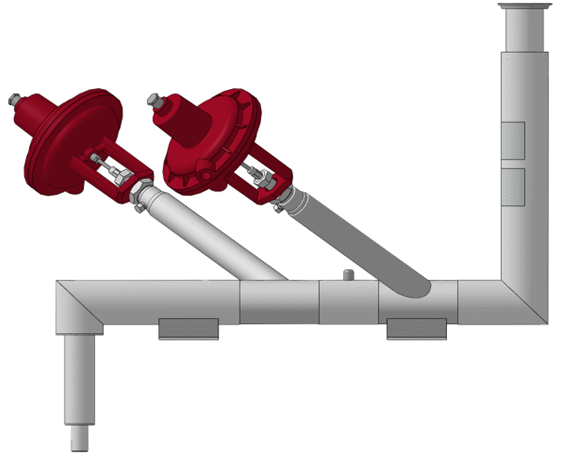

- Cooling: Liquid nitrogen direct injection refrigeration, equipped with InfitrolTM proportional control valve and safety valve

- Heating: 3 groups of heating wire equalization control, open nickel-chromium heating wire heating system

Vibration:

- 3 axial 6 degrees of freedom (6DoF) vibration

- The vibration frequency range is 5-10000Hz, and 90% of the vibration energy is distributed in 5-4000Hz

- Vibration intensity up to 100Grms (empty platform)

- Special ceramic-coated vibrating tables

- Air hammers and vibrating tables are backed by a three-year unconditional commercial warranty

|

|

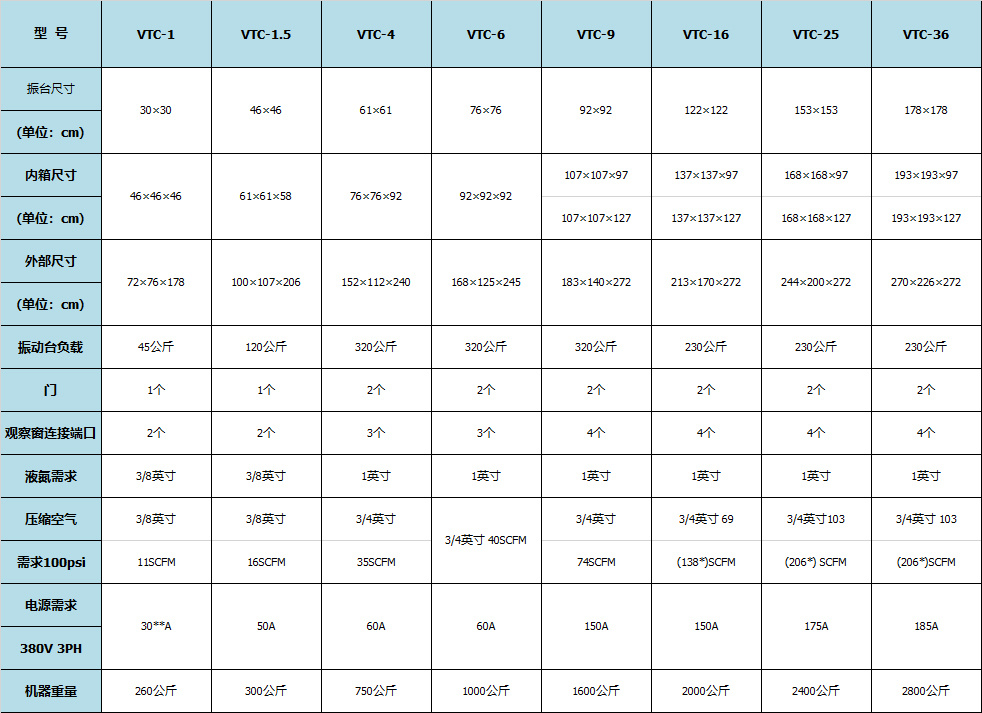

Specifications:

Applications:

The HALT/HASS system designed by HANSE has more than 20 years of R&D and practical experience, and is recognized as the fastest reliability test for electronic, electromechanical and other products.

One of the most effective methods can stimulate product defects in a short period of time and reduce the cost of product development, design and repair; improve the reliability of the product,

Accelerate time to market. It is widely used in electronics, communications, automobiles, aerospace, aviation, military industry, medical equipment, energy equipment and other fields.

Application Cases:

2. Magnetic card fixture 100 times unit test

3. HP printer paper feeding device humidity test

4. Military industry large load 500Lbs test

5. Hybrid vehicle HALT test

6. Lighting controller HALT test

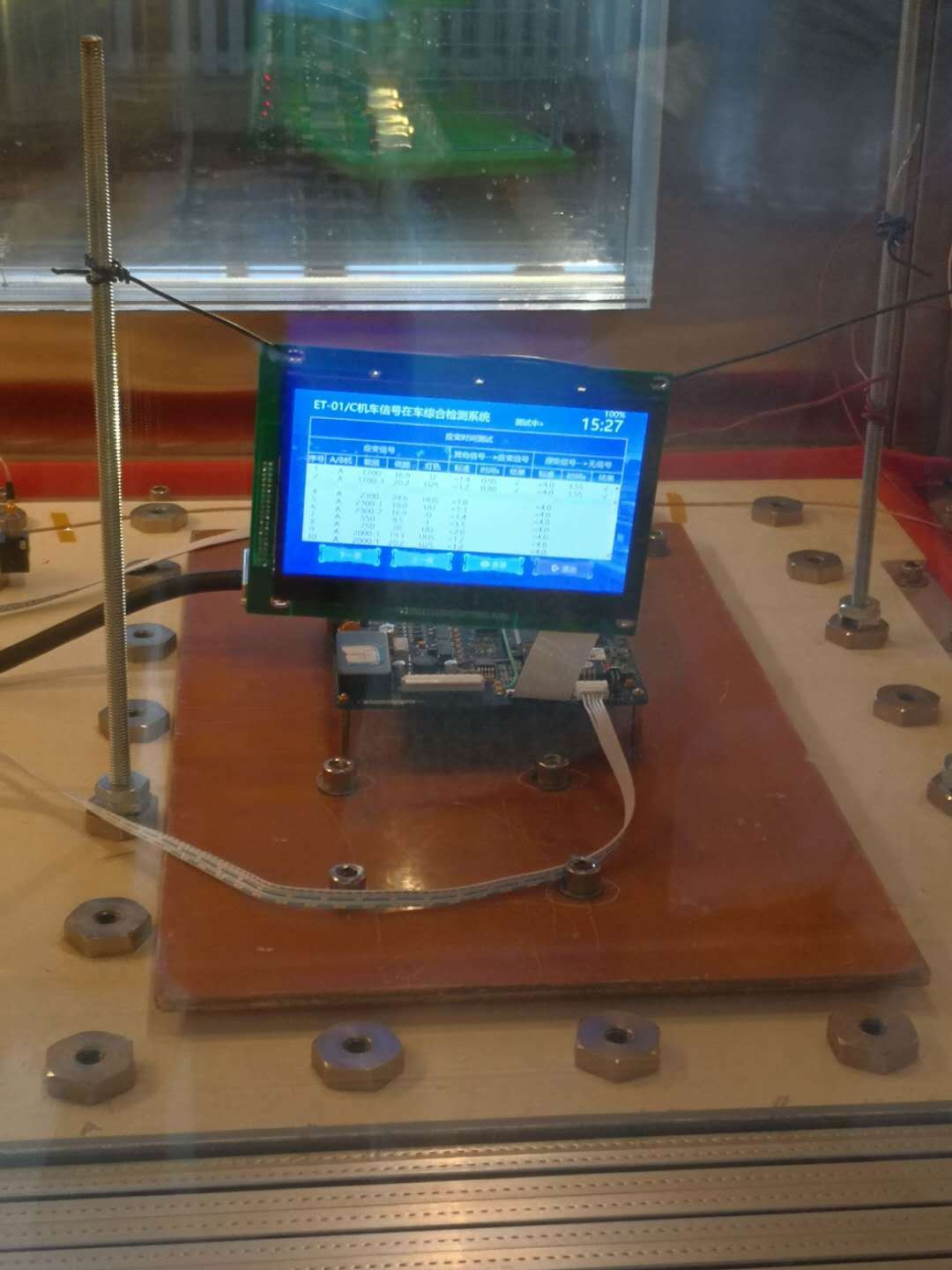

App Image:

(Click on the picture to watch the video of the HASA screening test of the circuit board)

Customer Base:

Domestic and foreign customers, including 3C industry, automotive industry and research center, etc.