CAPVIDIA QIFmaster MBD model quality management solution leads industrial manufacturing enterprises to successfully start the MBD process automation journey!

Release time:

2025-09-10 11:51

Source:

With the advancement of industry 4.0 and digital transformation, model-based definition ( MBD ) has become a core technology in manufacturing, replacing traditional 2D drawings with 3D digital models to achieve full-process digitization of design, manufacturing, and inspection. However, MBD the widespread application also brings challenges in data quality, interoperability, and automation. CAPVIDIA 's QIFmaster MBD model quality management solution has emerged, providing enterprises with a comprehensive solution to help them smoothly embark on MBD the journey of process automation. This article combines the latest academic research, industry practices, and reliable data to explore how this solution drives transformation in manufacturing.

MBD The importance and current challenges of

MBD technology greatly improve efficiency from design to manufacturing by integrating geometric and non-geometric information (such as dimensions, tolerances, and material specifications) into 3D models. According to a report published by the Society of Manufacturing Engineers ( SME ) 2023 in recent years, companies adopting MBD have on average reduced 40% design change time and improved 20% production accuracy. However, MBD the complexity of models often leads to data quality issues, such as model errors, format incompatibility, or missing information, which can cause manufacturing delays and cost overruns. A paper published in the Journal of Manufacturing Systems 30% stated that up to MBD of manufacturing defects originate from model data inconsistencies, emphasizing the urgent need for robust quality management.

Digital transformation leaders such as General Electric ( GE ) and Boeing have taken the lead in adopting MBD processes and shared valuable experiences. GE After implementing MBD in aircraft engine production, - design-to-manufacturing closed-loop automation was achieved, shortening product development cycles by 25% and reducing scrap rates through real-time quality inspection. 15% Boeing used 787 in the Dreamliner project to integrate supply chain data, improving collaboration efficiency, but initially faced challenges in model verification, highlighting the necessity of automated quality management. MBD CAPVIDIA QIFmaster MBD

solution's core advantages The model quality management solution focuses on addressing the above challenges, providing end-to-end quality inspection and management functions. The solution is based on the

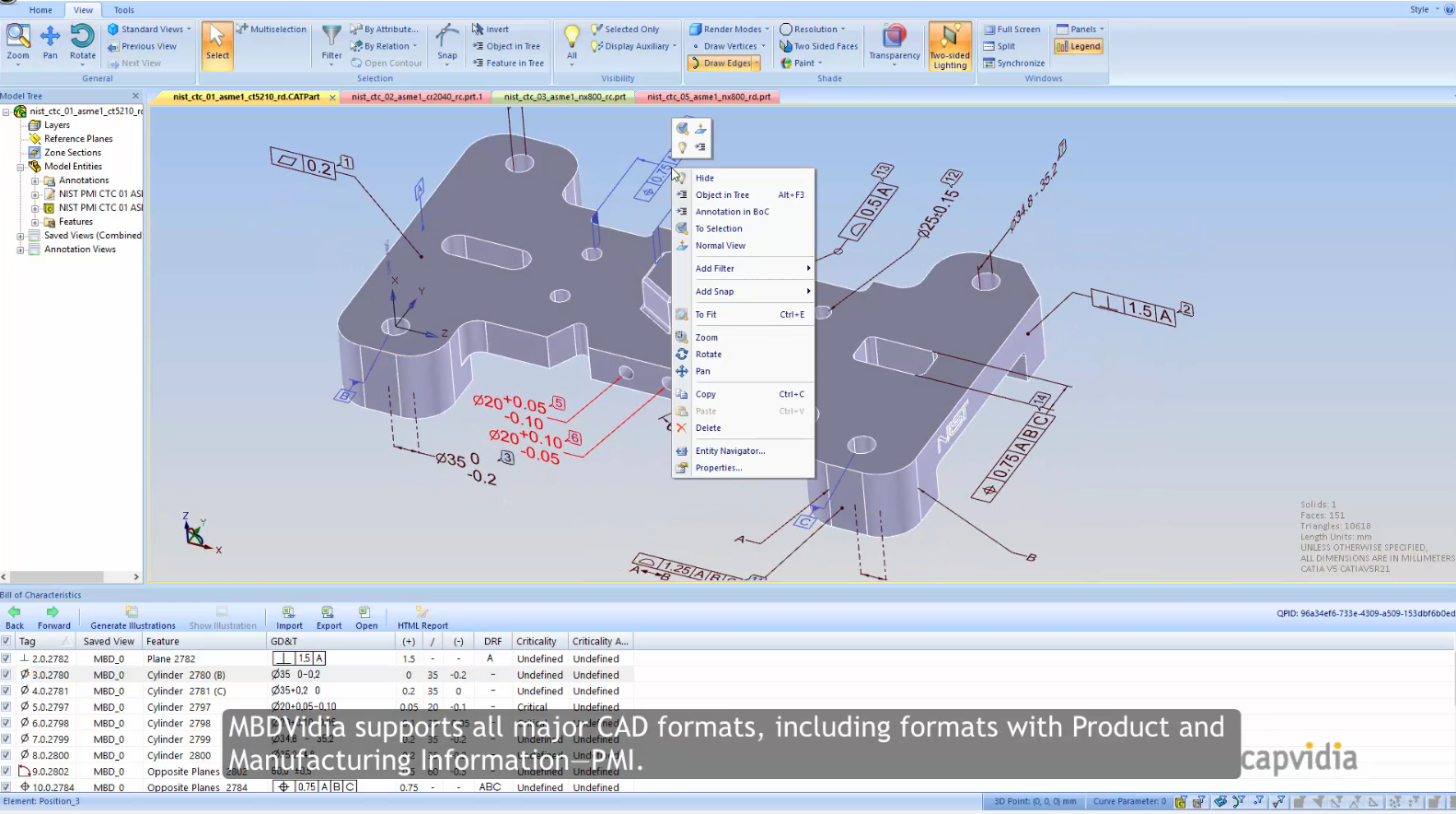

solution's core advantages QIF (Quality Information Framework) standard, ensuring model data integrity, compliance, and traceability. Key features include automatic model verification, digital twin integration, and cross-platform interoperability. Automatic model verification: QIFmaster (MBDVidia MBD and mainstream

- CAD system related plugins can automatically detect geometric errors, tolerance conflicts, and standard compliance in models, reducing manual intervention. According to the official technical white paper, companies using this solution can reduce model inspection time from hours to minutes, improving efficiency by more than MBD thanks to advanced algorithms and machine learning integration. This aligns with a year study published in the ) IEEE Transactions on Automation Science and Engineering MBD which showed that automated quality inspection can reduce the risk of human error by CAPVIDIA '[6]' 80% Digital twin integration: The solution supports real-time synchronization between models and the physical world, enabling 2022 predictive maintenance and continuous improvement. For example, Siemens Digital Industries implemented a similar approach at its Amberg plant, achieving dynamic optimization of production lines through digital twins, increasing equipment utilization by 25% QIFmaster compatibility ensures seamless integration with mainstream 。

- PLM MBD (Product Lifecycle Management) systems such as Teamcenter and 10%。 Windchill to promote automated data flow. Interoperability and standardization: The standard is promoted by the American Society for Quality ( ASQ ) to ensure reliable data exchange within the supply chain. The solution strengthens this, helping enterprises comply with international standards such as ASME Y14.41

- A year article in the (Quality Information Framework) standard, ensuring International Journal of Advanced Manufacturing Technology emphasized that based on )推动,确保了 MBD 数据在供应链中的可靠交换。 CAPVIDIA 的方案强化了这一点,帮助企业遵守国际标准如ASME Y14.41。一篇2023年《International Journal of Advanced Manufacturing Technology》的文章强调,基于 (Quality Information Framework) standard, ensuring The solution can reduce 50% data conversion loss and improve supply chain collaboration efficiency.

Leading enterprises to start the path of automation

For industrial manufacturing enterprises, starting MBD process automation is not achieved overnight, but requires a gradual strategy. CAPVIDIA QIFmaster The solution supports modular deployment, enabling enterprises to expand from pilot projects to full plant integration. Experiences from leading digital transformation enterprises show that the key to success lies in combining technological tools with organizational change. For example, Toyota prioritized employee training and established a quality culture before introducing automation tools, ultimately achieving zero-defect manufacturing. MBD When promoting automation, Toyota prioritized employee training and established a quality culture before introducing automation tools, ultimately achieving zero-defect manufacturing. CAPVIDIA The solution provides training and support services to help enterprises transition smoothly (such as BALLOON2D helping enterprises 2D drawing digitization). Data shows that early adopters, such as a European automotive supplier, saw a return on investment (ROI) within the first year after implementing Windchill After implementation, ROI ) exceeded 200% mainly due to reduced rework and accelerated time to market. [10] 。

Looking ahead, with the integration of artificial intelligence and the Internet of Things (IoT), IoT ), MBD process automation will become smarter and more adaptive. CAPVIDIA QIFmaster The solution continues to innovate by integrating predictive analytics and big data, helping enterprises cope with increasingly complex manufacturing environments. According to McKinsey Global Institute's forecast, by 2030 the year, GDP will increase by 1.5 trillions of US dollars, with MBD technology playing a key role. In summary, solution's core advantages the model quality management solution, with its professionalism, reliability, and innovation, provides a solid foundation for industrial manufacturing enterprises, driving MBD process automation from vision to reality. By adopting such solutions, enterprises can not only improve operational efficiency but also gain a competitive edge in the fiercely competitive global market.

MBD Technology,CAPVIDIA QIFmaster Model Quality Management Solution,CAPVIDIA,MBD Workflow,Process Automation