Solving the challenge of 2D drawing digitization: extraction of annotation data information and automatic generation of bubble charts

Release time:

2025-09-08 11:22

Source:

At present, in the manufacturing and engineering fields, 2D drawings remain one of the most widely used forms of design expression. However, most of these drawings exist as unstructured images or CAD files, and their annotation information (such as dimensions, tolerances, notes, etc.) cannot be directly read by machines, becoming a "breakpoint" in data flow. How to efficiently extract this information and convert it into structured data to support model-based definition ( MBD ) workflows has become an urgent problem to solve in the industry.

From digitization to digitalization: structured extraction is key

2D The "digitization" of drawings only refers to scanning paper drawings into images or saving them in CAD formats, while "digitalization" means converting the information in drawings into computable and analyzable structured data. This transformation involves several specific tasks:

First, optical character recognition ( OCR ) and symbol recognition are fundamental. Traditional OCR technologies have high recognition rates for printed text, but engineering drawings mix handwritten text, special symbols, dimension lines, and leader lines, requiring targeted training combined with deep learning. For example, recent research combines convolutional neural networks ( CNN ) and graph neural networks ( GNN ) to achieve context-aware recognition of dimension annotations, improving accuracy to above 90% [1] [1]。

Second, semantic parsing and relationship reconstruction are core. Extracted text and symbols need to be assigned engineering semantics (e.g., "Ø10" is parsed as diameter Ø10 ), and their association with geometric features must be reconstructed (such as which hole a dimension belongs to). 10mm),并重建其与几何特征的关联(如某尺寸属于哪个孔)。 The IEEE white paper "Knowledge Representation in Intelligent Manufacturing" points out that this step relies on domain knowledge bases and rule engines to ensure data logical consistency. 《智能制造中的知识表示》白皮书指出,这一步骤依赖领域知识库与规则引擎,以确保数据逻辑一致。

Finally, structured data output is the landing point. Information needs to be output in standard formats (such as XML 、 JSON or STEP AP242 ) to facilitate integration into PLM/ERP systems or directly drive MBD processes. MBD The requirement is to fully embed product information into the 3D model, and the digitalization of drawings provides a reusable data source for historical drawings. 2D图纸的数字化正是为历史图纸提供可重用的数据源。

Mainstream tools: from semi-automation to AI-driven

Currently, there are various software products on the market supporting 2D drawing information extraction, but the degree of automation varies:

- AutoCAD with Data Extraction : supports extracting attribute data from DWG files but requires predefined block attributes, suitable for highly standardized drawings.

- Siemens Teamcenter Drawing Automation : offers batch processing and data export functions but depends on template configuration and has limited handling of handwriting and complex annotations.

- OpenText ™ InfoExtract : focuses on engineering document OCR classification but requires extensive manual proofreading.

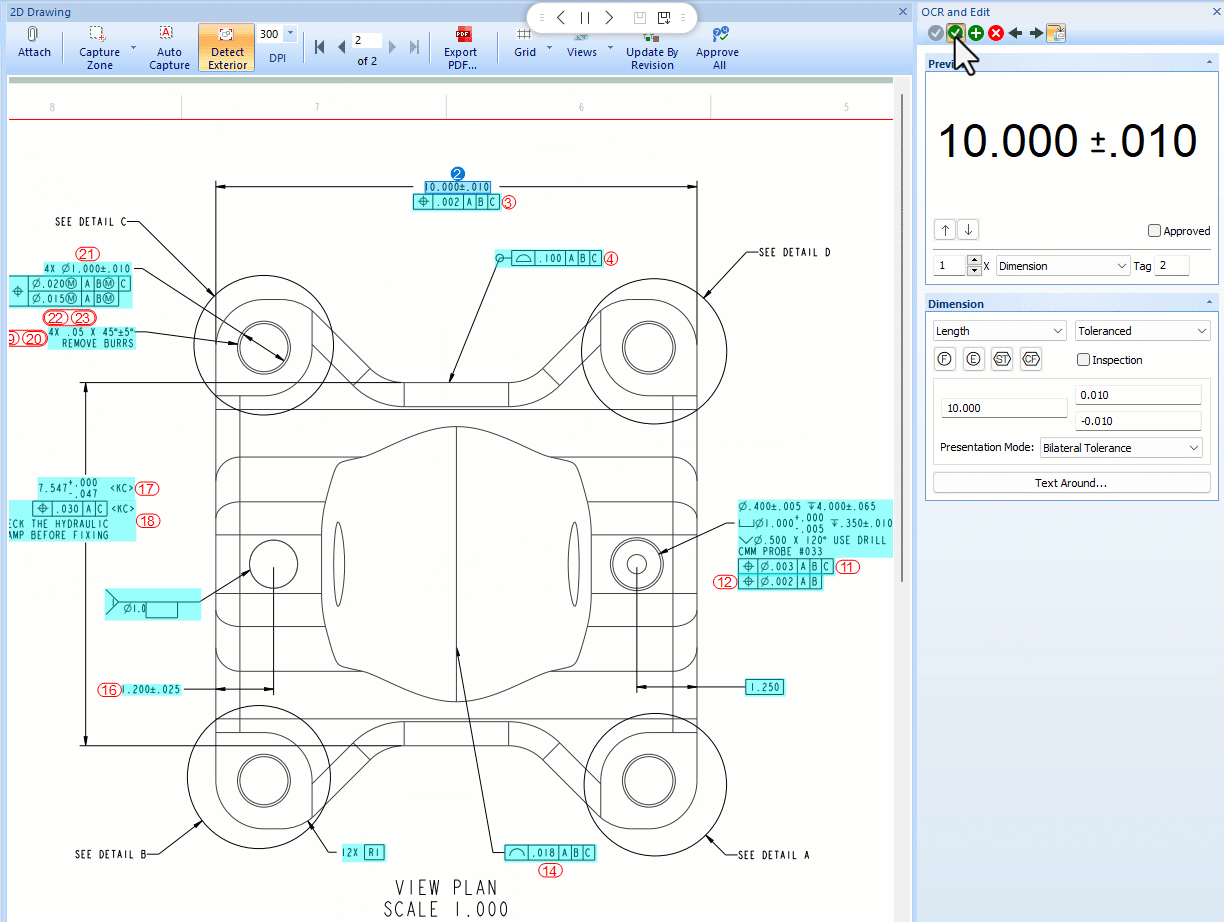

Most of these tools require manual intervention and struggle to handle drawing diversity. In recent years, AI-based solutions have been breaking through this bottleneck. For example, AI -based solutions such as CAPVIDIA company's BALLOON2D software ( MBDVidia version) include: 2D版本):

- High-precision recognition: by training on hundreds of thousands of drawing data, the software can recognize mixed fonts, symbols, and non-standard annotations, even adapting to partially damaged or low-resolution images.

- Automatic balloon map generation: traditional balloon maps ( Balloon Map ) require manual creation, whereas this software can automatically identify annotation positions and generate associated balloon numbers, greatly reducing first article inspection and review time. BALLOON2D Structured output: the software simultaneously generates feature lists (

- BOC, Bill of Characteristics ) and data reports (such as CSV Excel 、 ), and supports export to QMS platforms. or MBD 平台。

According to CAPVIDIA case studies, an aerospace company used it to process BALLOON2D historical drawings, achieving annotation extraction accuracy of 5000 and reducing man-hours by 95%,工时减少70% This tool not only accelerates the digitization of drawings but also MBD provides a seamless data foundation.

Conclusion

2D The digitization of drawings is not simply scanning, but rather AI transforming information into actionable data through rule engines. As the industry's demand for MBD grows, automated extraction tools such as BALLOON2D are becoming key drivers of transformation. In the future, systems integrating vision and knowledge AI will further connect the digital thread of design and manufacturing, unlocking the potential value of legacy drawings.

Automatic Bubble Chart Generation,2D Drawing Digitization,Drawing Annotation Recognition,Feature List,BALLOON2D,Drawing Information Extraction