What are the key points that industrial manufacturing enterprises need to pay attention to and consider when selecting professional software for 2D drawing digitization?

Release time:

2025-09-03 17:24

Source:

In the context of deep integration of intelligent manufacturing and artificial intelligence technologies, drawings serve as the core data carrier throughout the entire project lifecycle, and their management efficiency directly affects project progress and quality. For industrial manufacturing enterprises, the digitization of 2D drawings is not merely about converting paper drawings into electronic files, but a profound transformation from datafication to digitization, laying a solid foundation for the future comprehensive implementation of MBD (Model Based Definition).

Core value and transformation work of 2D drawing digitization

In traditional manufacturing, 2D drawing management has long faced many challenges: slow drawing retrieval, frequent version conflicts, and low collaborative design efficiency. Achieving the transformation of 2D drawings from datafication to digitization requires completing a series of specific tasks. A systematic architecture design needs to be established, adopting a dual-track architecture of "relational database + distributed file system." Metadata (such as drawing codes, versions, permissions, etc.) is stored in the relational database, while the distributed file system is used to store original files in various formats. Multimodal data processing is crucial. The system needs to support conversion of 2D drawing formats like DWG/PDF/SVG, as well as lightweight processing of 3D formats such as Solidworks, Inventor, CATIA, and UG. An intelligent coding system is the core of digitization, establishing five-dimensional coding rules combined with an auto-encoder to achieve automatic classification of drawings.

Comparison of mainstream 2D drawing digitization software tools

There are various 2D drawing digitization software tools on the market, equipped with data extraction and structuring functions, especially bubble chart generation capabilities.

German Elsys Bubble Chart Annotation Software Performs excellently in CAD drawing processing, supporting direct recognition of DWG/DXF formats and one-click selection functionality. Test data shows the software recognizes 40 known dimension types in only 18 seconds, with the complete processing workflow taking no more than 2 minutes and 29 seconds.

Heidejie Technology Quality Management Master QIF Manager Pro Provides a dimension-by-dimension recognition solution, can automatically associate measuring instruments and automatically fill bubble chart areas, enabling one-click export of inspection plans. The software processes 40 dimensions in about 5 minutes and 58 seconds.

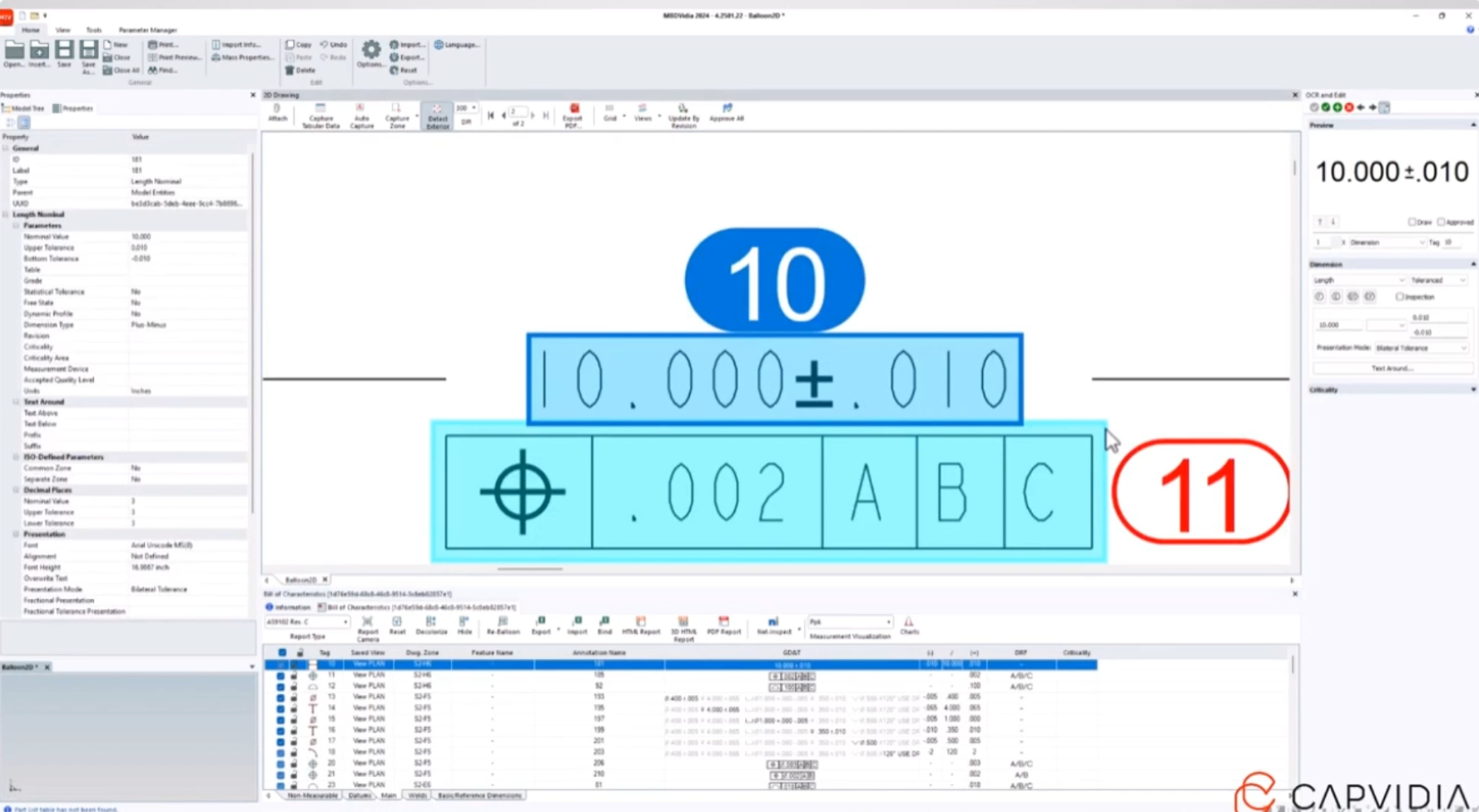

Balloon2D software launched by US CAPVIDIA as the 2D version of MBDVidia Based on AI OCR recognition technology, it has significant advantages in PDF drawing processing. The software can recognize PDF drawings with one click, automatically generate bubble charts, BOC (Bill of Characteristics), and export data reports. It aims to enable flat drawings to play a role in the MBD workflow. In practical application, after a certain automotive parts company used Balloon2D, the single project drawing processing time was reduced from 6 hours to less than 5 minutes, inspection report preparation efficiency increased by 90%, and human annotation error rate decreased by 90%. The company saves at least 800,000 yuan annually in labor costs. For enterprises wishing to adopt the MBD workflow, Balloon2D provides a bridging function, allowing traditional flat engineering drawings to continue to be effective in the new MBD workflow, outputting forms that meet AS 9102 and ITAF 16949 quality system requirements.

Key considerations for enterprise selection

Industrial manufacturing enterprises need to focus on several core points when selecting 2D drawing digitization software.

Technical capability is the fundamental consideration. The software should support various commonly used drawing formats (CAD, PDF, images, etc.) with high-precision recognition and efficient processing speed. The system architecture of the software is also important; it should support a hybrid storage engine that can store metadata in relational databases and original files in distributed file systems.

Integration and compatibility are equally critical. Excellent software should seamlessly integrate with existing enterprise systems such as PLM and PDM, support workflows compliant with ISO 23952 Quality Information Framework (QIF) standards, and be able to output neutral MBD models (STEP AP242 and QIF formats).

Benefit-to-output ratio should not be overlooked. Enterprises need to evaluate the actual benefit-to-output ratio of the software, including quantitative indicators such as time savings, error reduction, and cost savings. Consideration of software deployment methods, learning curves, and subsequent maintenance costs is also important.

Data shows that enterprises adopting digital drawing management can reduce drawing error rates by 63% and save an average of 1.2 million USD per project in change costs. In the coming years, 2D drawing digitization software will further integrate AI technology to achieve real-time mapping based on digital twins and blockchain-based intellectual property protection. Choosing the right 2D drawing digitization software has become an indispensable part of enhancing the core competitiveness of manufacturing enterprises.

Professional software for 2D drawing digitization,BALLOON2D,Automatic Bubble Chart Generation,One-click export of feature list,2D Drawing Annotation Recognition