How to extract a company's historical drawing data for use in the MBD workflow? You need to look at the 2D version of the MBDVidia Suite software — Balloon2D!

Release time:

2025-09-11 13:09

Source:

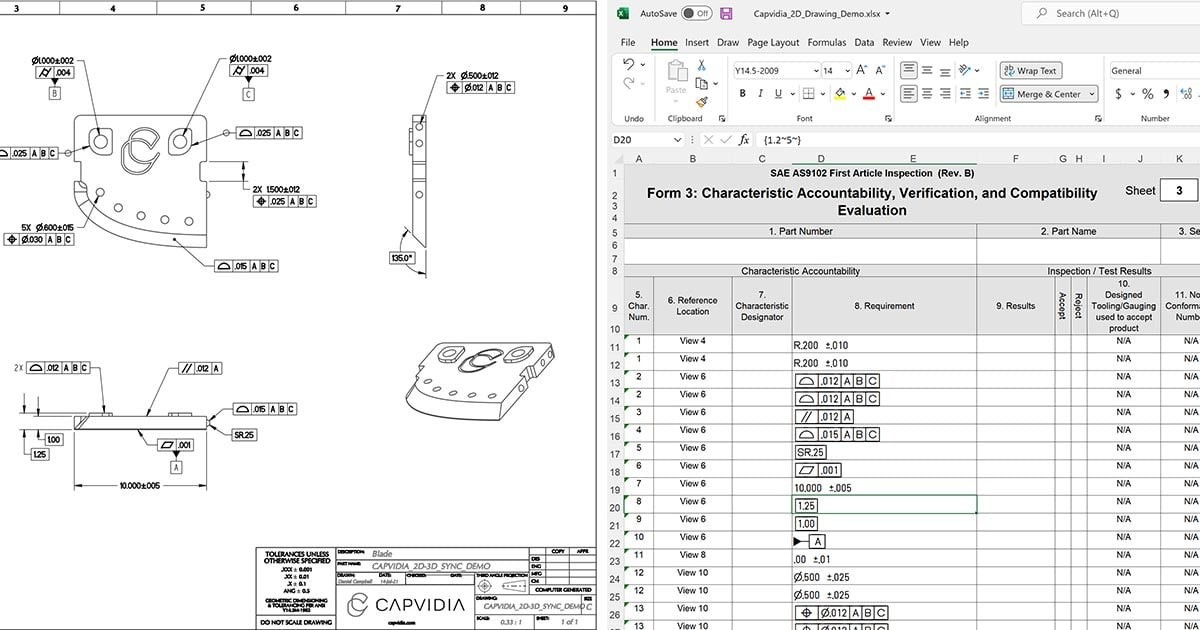

In the wave of digital transformation in manufacturing, the vast amount of 2D drawings accumulated by enterprises has become valuable data assets. How to effectively extract annotation information from these drawings and integrate it into model-based definition (MBD) modern workflows is a practical challenge faced by enterprises. MBD )-based modern workflows is a practical challenge faced by enterprises. Balloon2D The software uses advanced data extraction technology to convert dimensions, tolerances, and technical requirements from 2D drawings into structured digital information, providing high-quality data input for workflows and helping enterprises achieve a smooth transition to digital manufacturing. MBD Workflows provide high-quality data input, helping enterprises achieve a smooth transition to digital manufacturing.

01 Data Extraction: From Drawings to Structured Information

Balloon2D First, the 2D drawings are intelligently parsed to accurately identify various annotation elements within the drawings. The software can extract key manufacturing information such as dimension annotations, geometric tolerances, surface roughness symbols, notes, and technical requirements. The extraction process is not just simple data capture; more importantly, it establishes logical relationships between data. The system automatically identifies annotation objects, annotation values, and tolerance ranges, organizing them into a structured data format. This structured data provides standardized input for subsequent workflows, ensuring the readability and usability of information within digital systems. The extracted data can be directly used to generate inspection plans, quality documents, and process instruction files. MBD Workflows provide standardized input, ensuring the readability and usability of information within digital systems. The extracted data can be directly used to generate inspection plans, quality documents, and process instruction files.

02 Data Application: Empowering MBD Workflows

The extracted 2D drawing data plays an important role in workflows. MBD Although it cannot yet be directly matched to 3D models, this data provides critical manufacturing information supplements for the MBD environment. In product quality control, the extracted data can automatically generate inspection plans that comply with standards such as AS9102、 PPAP . Inspectors can directly use this structured data to guide inspection work, ensuring products meet the original design intent. During process planning, the extracted dimension and tolerance data provide process engineers with accurate manufacturing requirement information, helping them develop more precise machining and assembly processes, reducing quality issues caused by information misunderstandings.

03 Data Integration: Building a Bridge Between 2D and 3D

Although current technology cannot yet achieve 2D direct mapping from data to 3D models, the Balloon2D extracted structured data provides an important foundation for this process. This data can serve as a reference benchmark in workflows, ensuring consistency between 3D digital manufacturing and traditional 2D design. Engineers can use the extracted data to establish corresponding Product Manufacturing Information (PMI) in the system, and through manual verification and adjustment, ensure that annotations in the 3D model remain consistent with the original design intent. This working method not only preserves historical design knowledge but also provides enterprises with a gradual digital transformation path. Enterprises can gradually integrate traditional design data into modern digital platforms without affecting existing production. MBD Engineers can use the extracted data to establish corresponding Product Manufacturing Information (PMI) in the system, and through manual verification and adjustment, ensure that annotations in the 3D model remain consistent with the original design intent. This working method not only preserves historical design knowledge but also provides enterprises with a gradual digital transformation path. Enterprises can gradually integrate traditional design data into modern digital platforms without affecting existing production. MBD Product Manufacturing Information (PMI) PMI Through manual verification and adjustment, ensuring that annotations in the 3D model remain consistent with the original design intent. This working method not only preserves historical design knowledge but also provides enterprises with a gradual digital transformation path. Enterprises can gradually integrate traditional design data into modern digital platforms without affecting existing production.

04 Quality Traceability: Ensuring Data Consistency

Balloon2D The extracted data plays a key role in quality traceability. By digitizing 2D drawing data, enterprises can establish complete digital quality records, ensuring data consistency throughout the entire process from design to manufacturing. During first article inspection and product validation stages, the extracted data provides reliable inspection evidence. Inspectors can develop inspection plans based on structured annotation data to ensure product quality meets original design requirements. Meanwhile, digitally stored annotation data facilitates traceability and retrieval, providing data support for quality problem analysis and improvement, helping enterprises continuously enhance product quality levels.

05 Future Outlook: Intelligent Data Integration

With technological development, the integration of 2D drawing data and 3D MBD models will become more intelligent. Currently, Balloon2D's data extraction and structured processing lay a solid foundation for future automatic matching. The industry is exploring AI-based 2D-3D data association technologies, which are expected to achieve intelligent mapping of 2D annotation information to 3D models in the future. This will further shorten product development cycles and improve manufacturing accuracy. Even at the current stage, Balloon2D's data processing capabilities have already brought significant efficiency improvements to manufacturing enterprises, helping them take solid steps on the path of digital transformation. Balloon2D, through intelligent data extraction technology, converts manufacturing information from traditional 2D drawings into structured data usable in MBD workflows, building a bridge connecting traditional design and digital manufacturing for enterprises.

BALLOON2D,2D Drawing Data Extraction,2D Drawing Digitization Software,2D Drawing Bubble Diagram,MBD Workflow

Previous Page