What can the new DIC strain measurement technology do in the context of digital and intelligent transformation?

Release time:

2024-12-09 12:00

Source:

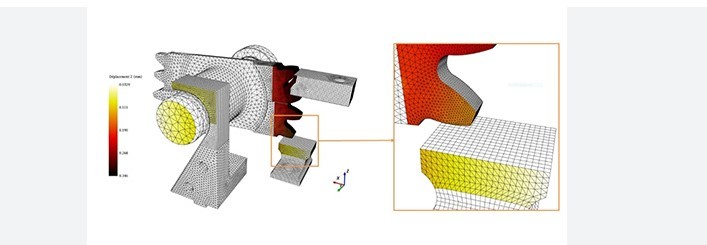

In the process of digital transformation, virtual simulation technology is becoming increasingly popular due to its cost-effectiveness, strong safety, and repeatability. Traditional engineering validation relies on cumbersome experiments and a large number of physical tests, which are not only time-consuming and labor-intensive but also costly. EikoTwin DIC technology builds an invisible bridge between traditional engineering experiments and physical tests, allowing us to directly display experimental measurement results on simulation models, provide optimization suggestions for simulation models, and promote collaboration between simulation and experimental testing, greatly reducing the number of experiments and saving valuable time and resources.

Figure 1 EIKOTWIN DIC supports the direct display of experimental measurement data on the grid of the FM model, allowing for direct comparison and validation.

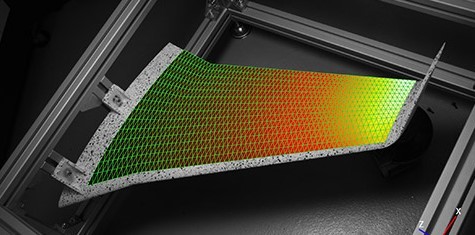

EikoTwin DICThe technology employs advanced digital image correlation principles, capturing images before and after deformation through digital photography, selecting window grayscale features, and calculating displacement through grayscale comparison and precise matching algorithms, thus obtaining full-field displacement data, from which strain fields can be calculated. This technology allows each sub-window to represent a data point, equivalent to a virtual strain gauge at that point, greatly improving measurement accuracy and efficiency. EikoTwin DIC technology conducts full-field three-dimensional strain measurements based on simulation models, overcoming the limitations of traditional measurements, quickly identifying the weakest design points, avoiding over-design and under-design, while reducing the possibility of fatigue failure caused by stress concentration, effectively improving simulation accuracy and achieving seamless integration of simulation and experiments.

Figure 2 EIKOTWIN DIC supports full-field measurement.

ANSYS, ALTAIR, DASSAULT SYSTEMES, MBDA, SAFRAN, ARIANE GROUP and other well-known companies in the industry are applying EikoTwin DIC technology. From the automotive and railway industries to aerospace and defense fields, EikoTwin DIC technology has demonstrated its excellent performance and wide applicability.

Figure 3 Some clients currently using EIKOTWIN DIC.

In the upcoming online seminar, we will delve into the principles and application cases of EikoTwin DIC technology, demonstrating how it directly displays experimental measurement results on simulation models, and how this technology promotes collaboration between simulation and experiments, reducing a large number of experiments and saving time, manpower, and financial costs. We look forward to your participation in witnessing how this technology leads a new trend in engineering validation.

Figure 4 "Interpretation of New DIC Strain Measurement Technology in Digital Transformation" Online Seminar

Online Seminar Details

Title: Interpretation of New DIC Strain Measurement Technology in Digital Transformation

New DIC Technology Speaker: Guo Qiang, Beijing Qiaozhe Technology Co., Ltd.

First Session Time: December 11, 2024 (Wednesday) 15:00——16:00

Second Session Time: December 17, 2024 (Tuesday) 19:00——20:00

Tencent Meeting: First Meeting 929-719-990

Second Meeting 908-557-504

EIKOTWIN DIC,Comparison and validation of simulation and experimental measurements.,DIC Strain Measurement,New DIC Strain Measurement Technology,Three-dimensional full-field strain measurement,Non-contact optical strain measurement

Previous Page