DIC Strain Measurement Technology Consulting & Services

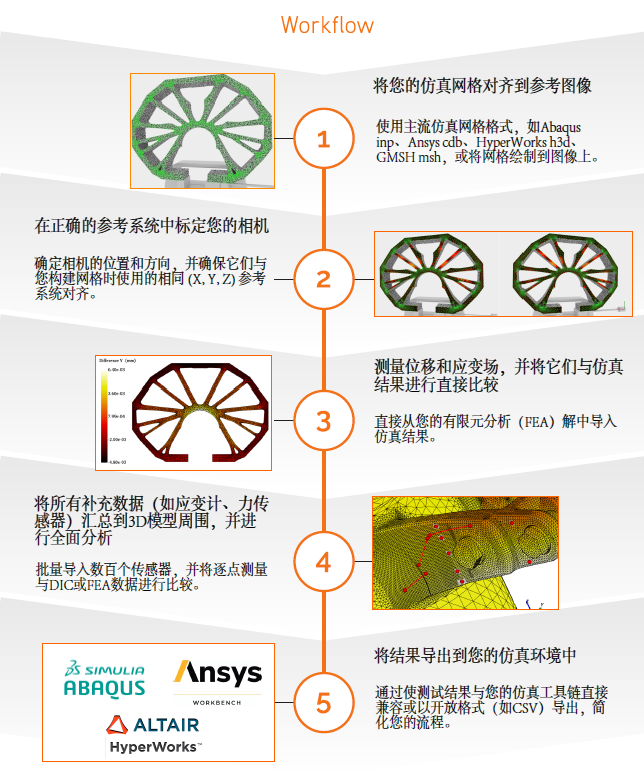

In order to help customers achieve high-precision strain and deformation analysis, our company provides testing services based on EikoTwin DIC technology. As the only digital image correlation technology built with simulation verification as the core, EikoTwin DIC combines high-resolution image capture, accurate digital image correlation technology (DIC) and advanced data processing capabilities to provide customers with high-quality strain field, displacement field and deformation analysis data, which is suitable for mechanical property testing and CAE verification of various complex materials and structures.

EikoTwin DIC testing service provides customers with comprehensive non-contact measurement solutions, which are widely used in materials research, product design verification, fault diagnosis, fatigue testing and other fields. Through this technology, customers can obtain more accurate full-field strain data than traditional strain gauges and sensors, helping to achieve more scientific engineering analysis and optimization.

This note will introduce the content, process, charging standard, customer responsibilities and other relevant terms of the EikoTwin DIC testing service in detail, so as to ensure that customers understand all important information when enjoying the service.

1. EikoTwin DIC testing service scope

Our EikoTwin DIC testing service covers a wide range of application areas, including the following aspects:

1. Full-field strain analysis

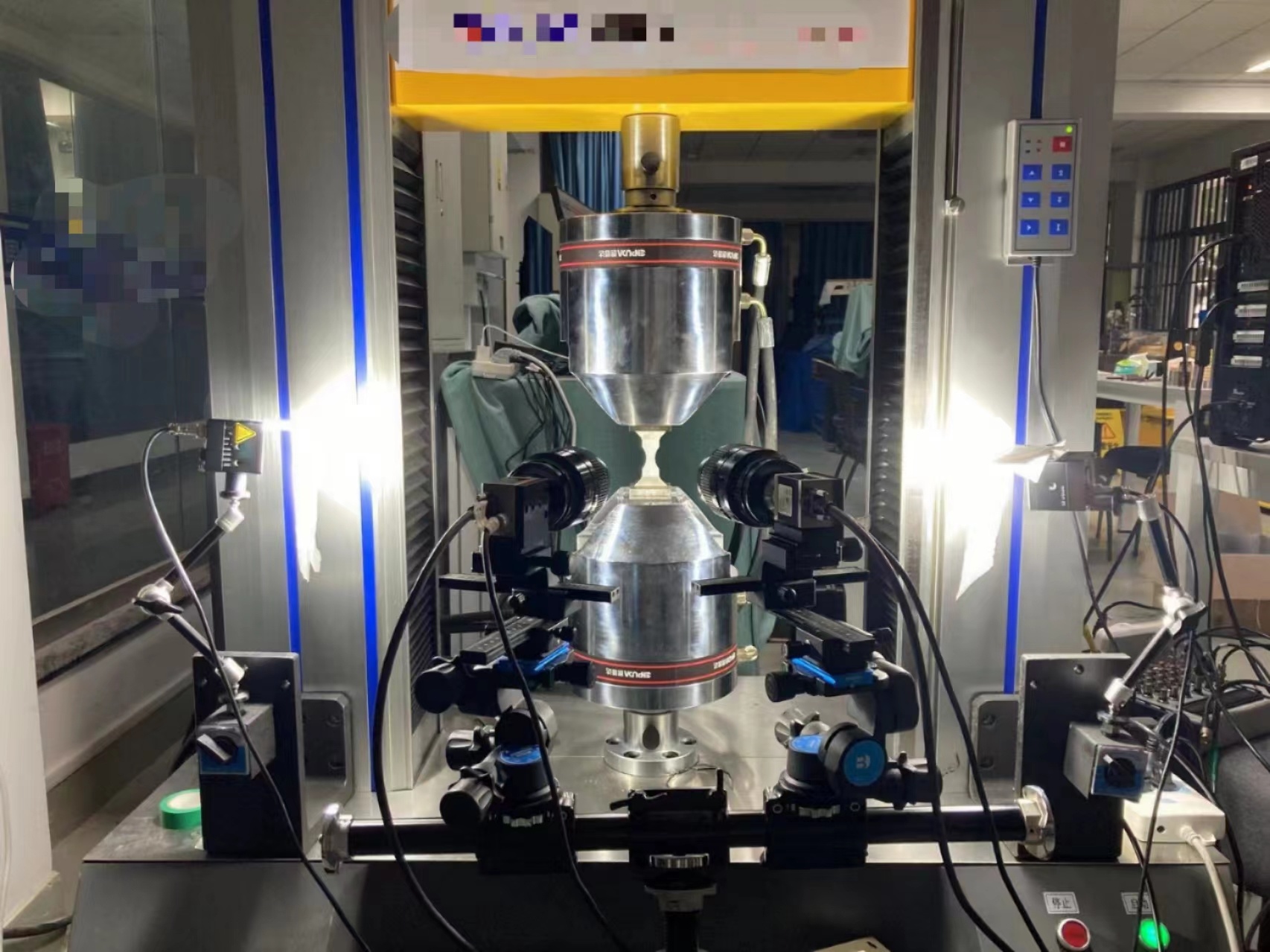

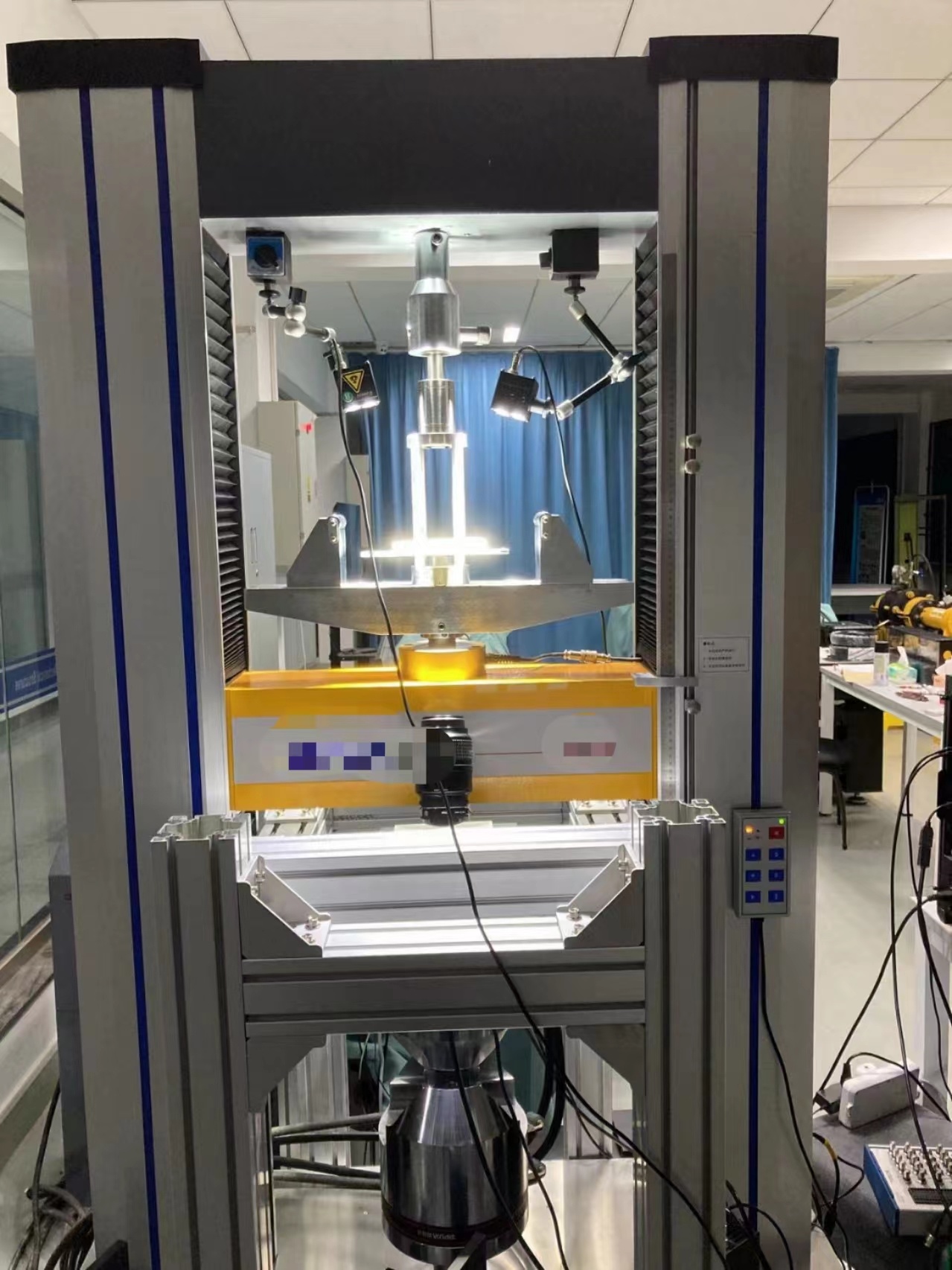

The EikoTwin DIC system monitors the surface deformation of the sample under loading conditions in real time and obtains accurate strain distribution data.

2. Displacement and deformation measurements

Under different loading conditions, the full-field displacement and deformation field data of the sample can be obtained, which is suitable for complex multiaxial loads, thermo-mechanical coupling tests, etc.

3. Fatigue and fracture analysis

The EikoTwin DIC system is used to track and analyze the fatigue process, crack propagation, and strain concentration of materials or structures with high precision, and support fatigue life prediction and fracture toughness evaluation.

4. Modal analysis and vibration testing

The EikoTwin DIC system was used to analyze the dynamic response of the structure in the vibration state, and the dynamic test data such as vibration mode, frequency response, and modal characteristics were obtained.

5. Thermal strain and temperature field analysis

Thermal-mechanical coupling analysis is performed under high or low temperature conditions to obtain data such as thermal strain field and temperature distribution, supporting thermal failure analysis and temperature control optimization.

6. Customized DIC test

Personalized testing services are provided according to the specific needs of customers, such as DIC analysis under extreme temperatures, special loading conditions, etc.

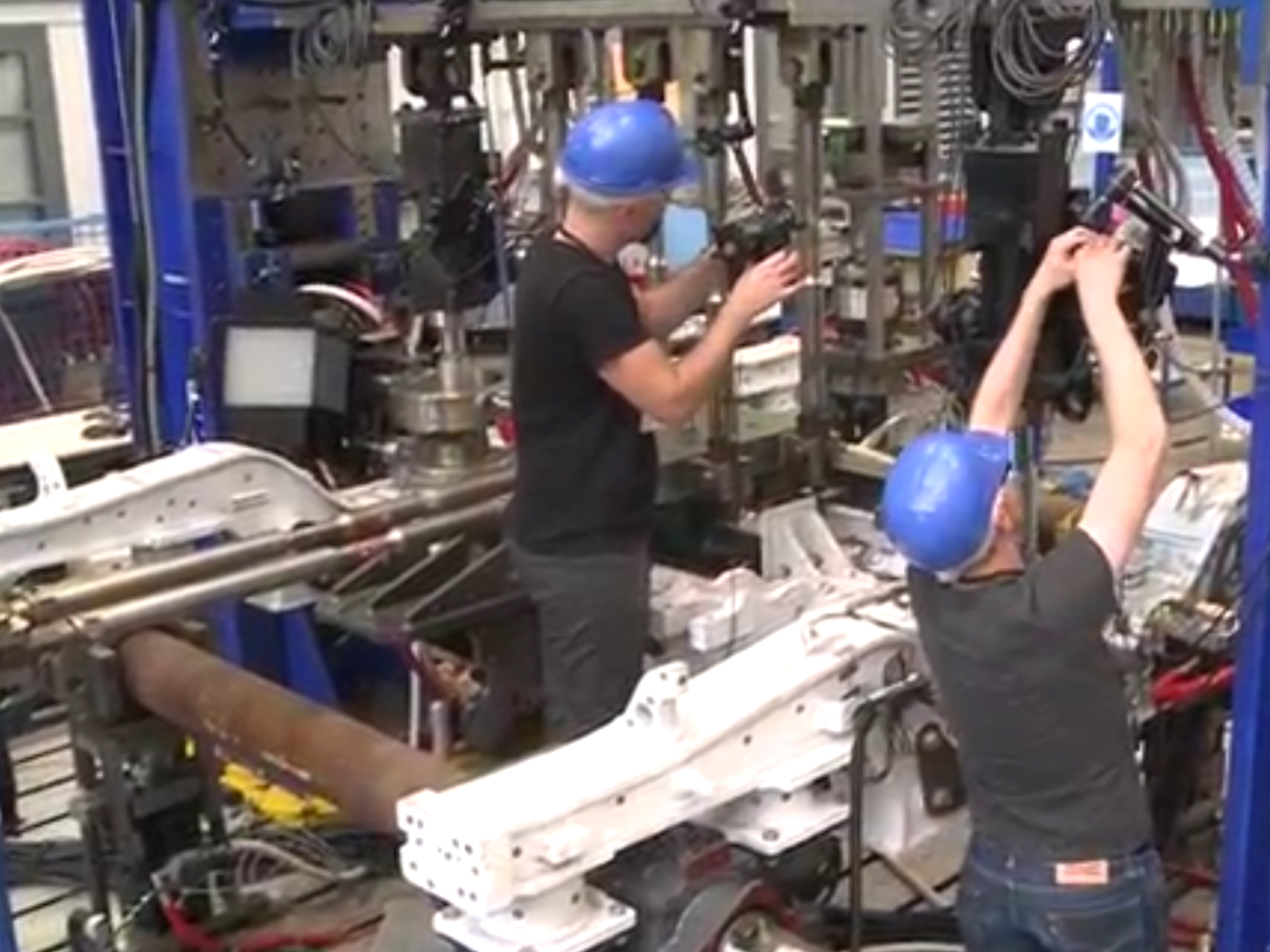

7. On-site testing service

Provide on-site testing services to help customers directly collect data at the production site, in the test environment, or under special working conditions. With on-site testing, customers are able to obtain test data in real time and conduct on-site analysis.

2. EikoTwin DIC testing service process

1. Consultation of requirements and confirmation of test plan

* The customer communicates with our technical support team to confirm the specific test requirements and test objectives.

* Customers provide 3D digital model documents of the samples to be tested (CAD files of samples can also be provided, we will assist in 3D modeling as appropriate), expected loading conditions and other information, so that our company can customize a suitable test plan.

2. Sign a service agreement

* According to the negotiation between the two parties, our company will formulate a detailed test plan and cost list, and clarify the test content, cycle and deliverables.

* The two parties signed a formal EikoTwin DIC testing service agreement to ensure the transparency and clarity of the service content and fees.

3. Sample preparation and submission

* The customer submits the samples to be tested to our company according to the requirements of the agreement, and the samples need to meet the basic requirements of EikoTwin DIC test (such as surface treatment, dimensional calibration, etc.).

* Our company conducts a preliminary inspection of the samples, and carries out the necessary pretreatment and calibration according to the test requirements.

4. DIC test implementation

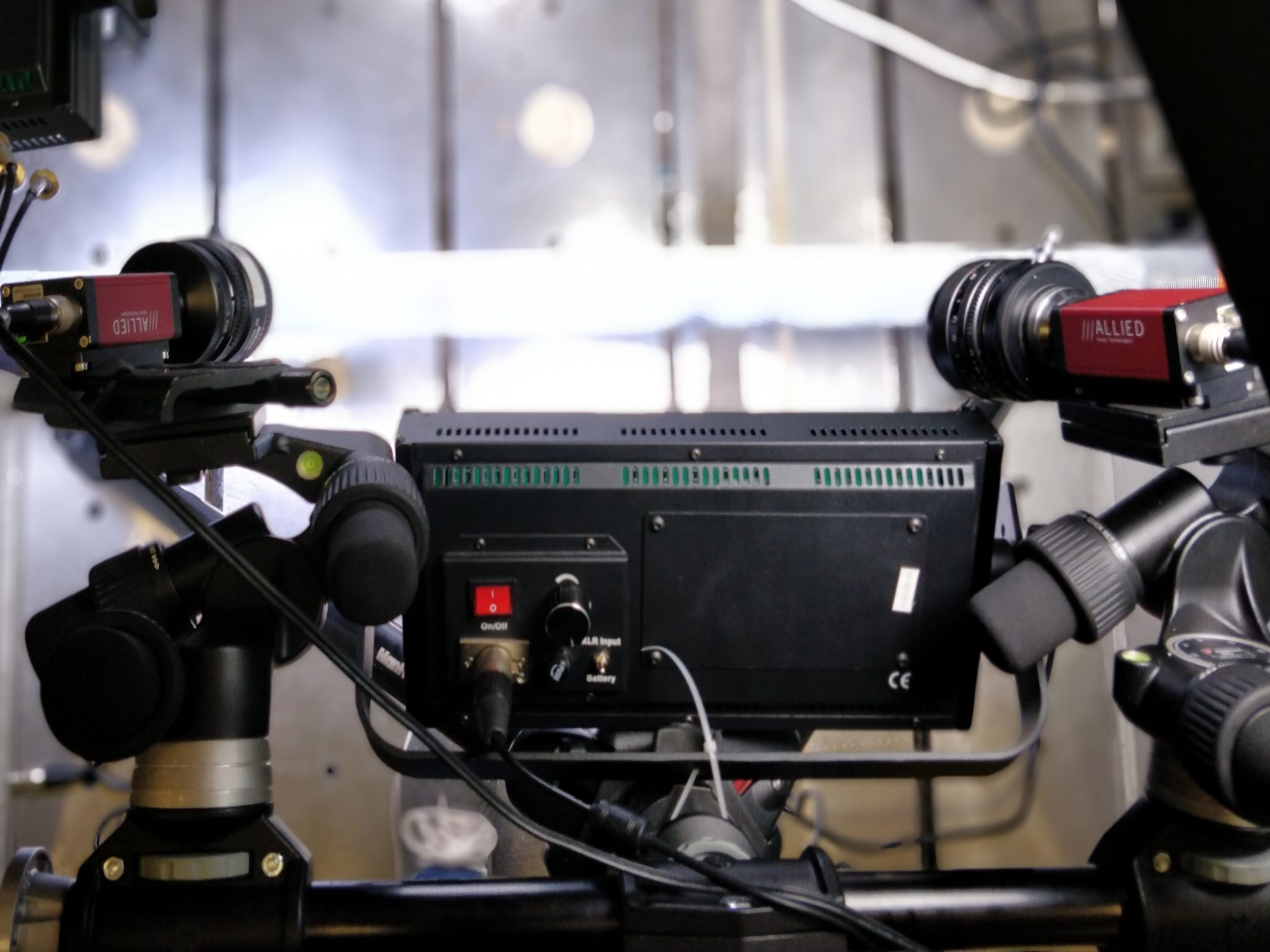

* Our company uses the EikoTwin DIC system for data acquisition, which uses a high-resolution camera to capture the full-field deformation of the sample under loading, and accurately measure the strain, displacement, and deformation.

* During the test, the data is collected and transmitted in real time to ensure the accuracy and reliability of the data.

5. On-site test implementation

* Our company will send a technical team to the site designated by the customer to conduct DIC testing. The on-site test includes sample layout, data collection, real-time monitoring and other links.

6. Data analysis and report generation

* After completing the test, our engineers analyze the collected data and generate data analysis results such as strain distribution map, displacement field, and deformation mode.

* Generate detailed test reports based on test data and customer requirements, including data analysis, test results, conclusions and recommendations.

7. Delivery and follow-up support

* Test reports and data files will be delivered to the customer. If customers have any questions, they can get further answers and assistance through the technical support team.

* Our company provides follow-up technical support to ensure that customers can fully understand the test results and apply them effectively.

3. EikoTwin DIC testing service charging standard

1. Basic testing services

* Strain analysis: Pricing is based on the number of samples, test complexity, and experimental environmental conditions.

* Displacement & Deformation Measurements: Priced based on loading conditions and test complexity.

* Fatigue & Fracture Analysis: Pricing based on test material, test conditions, and loading mode.

2. Advanced Testing Services

* Thermal strain and temperature field analysis: including high temperature or low temperature test environment, the specific cost is determined according to the experimental environment and sample requirements.

* Modal Analysis & Vibration Testing: Pricing is based on test frequency, number of vibration modes, and experimental conditions.

3. Customized testing services

* Customized testing according to the specific needs of the customer, the cost is assessed according to the complexity and workload of the specific project.

4. Data analysis and report generation

* Standard Data Analysis Report: Included in the above testing services.

* Advanced Data Analysis & Post-Processing: Included in the above testing services.

5. Sample transportation and handling

* The customer is responsible for the shipping cost of the sample. If we need our company to assist in transportation, the relevant fees will be charged separately according to the actual situation.

6. On-site testing service

* Basic door-to-door testing service: Depends on the situation, suitable for simple tests with a single loading case.

* Complex on-site testing service: According to the specific situation, it is suitable for complex tests such as multiple working conditions, multiple samples, and long-term data collection.

* Transportation and accommodation expenses: If the test location is outside the company's regular service area, the customer will be responsible for the relevant transportation, accommodation and other expenses.

4. Precautions for proxy testing services

1. Sample requirements

* Customers need to ensure that the samples provided meet the basic requirements of DIC testing, such as sufficient texture on the surface of the sample for the camera to capture the image.

* The size, shape, and number of samples need to be specified in the protocol. If the sample does not meet the requirements, our company will suggest to adjust the plan or provide sample pretreatment services.

2. On-site test environment

* For on-site testing services, customers are required to provide detailed information about the on-site environment (e.g., temperature, humidity, test equipment, etc.) in advance. In some special environments, customers may be required to provide additional equipment support or facility support.

3. Non-Disclosure Agreement

* Our company promises to keep all test data, sample information and related data strictly confidential for customers. All data is for the sole use of the customer and is never disclosed to any third party without the customer's authorization.

4. Test cycle

* The test cycle depends on the complexity of the project and the number of samples. Usually it takes 3-7 working days from sample start test to report delivery, excluding holidays. The specific period will be specified in the agreement.

5. Payment of Fees

* The cost of the testing service is divided into advance payment and final payment, usually 50% advance payment, which is paid before the start of the test, and the remaining fee is paid before the report is delivered.

* Payment methods include bank transfer, Alipay, WeChat Pay, etc.

6. Invoice Information

* All fees paid are inclusive of tax and can be invoiced.

7. Report Delivery and Amendment

* After completing the test, the customer will receive an electronic version of the test report. If there is any content that needs to be modified or supplemented in the report, the customer can submit it within 5 working days after the report is delivered, and our company will adjust accordingly.

5. Contact us

If you have any questions about the EikoTwin DIC testing service, or need further details, please feel free to contact us:

- Customer service number: 86-10-65610249

- Customer service email: marketing@deanwell.com.cn

- Official website: https://www.deanwell.com.cn

- Technical support online service: 17317384736 (same number on WeChat)

Thank you for choosing our EikoTwin DIC testing service. We will help you achieve accurate engineering analysis and optimization with advanced equipment, professional technical team and efficient service.