Quality and Reliability Verification

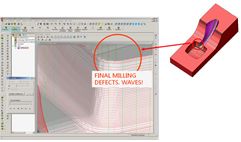

CAD file conversion quality verification

As the competition in the technology industry becomes increasingly fierce, the challenges of improving product development quality and shortening development timelines have become the primary issues that global manufacturers must face. Advanced countries such as the United States and Europe have long recognized the industrial impact of this problem and have actively introduced digital design and manufacturing technologies in recent years. In the modernization of the product development process, in addition to enhancing their own R&D capabilities, CAD/CAE/CAM systems are essential support tools.

Life testing

HALT (Highly Accelerated Life Testing) is used to strengthen products during the design phase, aiming to identify weak links in design and manufacturing processes, uncover operational and failure limits (to determine product specifications that meet customer needs), identify failure modes (causes and timing of failures), implement corrective actions, eliminate design and wear defects, and establish HASS baselines.

Environmental testing

Products must undergo environmental testing based on the conditions they may encounter during manufacturing, storage, transportation, and usage, to verify their ability to withstand environmental stresses. In practical applications, to avoid confusion and easily identify the true causes of product failures, major international companies typically conduct natural environmental tests, dynamic environmental tests, and combined environmental tests separately.

Material testing

The main purpose of material testing is to confirm the composition and properties of materials. To achieve this goal, Qiaozhe Technology provides comprehensive services to assist you in material testing.