Artificial intelligence excels in the PHM industry: Intelligent monitoring technology reshapes new patterns in health and industrial safety

Release time:

2025-06-10 12:01

Source:

The integration of artificial intelligence in the field of Prognostics and Health Management (PHM) is driving technological innovation with unprecedented depth and breadth, achieving significant breakthroughs in human health monitoring, industrial environment control, and advanced manufacturing. Multiple combinations of intelligent technologies are becoming the core force in ensuring health, improving quality, and safeguarding safety.

Sports Biomechanics + AI Visual Capture: The "Smart Coach" for Personal Health and Athletic Performance

A human motion biomechanics analysis platform that integrates high-precision motion capture systems with artificial intelligence algorithms is redefining health and sports management. By using high-speed cameras and wearable sensors to capture human motion trajectories in real time, the AI system analyzes key biomechanical parameters such as joint angles, muscle force distribution, and gait characteristics at millisecond levels. This provides athletes with movement optimization suggestions to precisely enhance athletic performance; in rehabilitation medicine, it quantifies recovery progress and guides personalized plan formulation; it also plays a key role in preventing daily sports injuries and correcting abnormal postures. The intelligent system is becoming everyone's exclusive "digital health coach."

Noise Prediction Software + Intelligent Detection Devices: The "Seer" and "Purifier" of Environmental Noise

Facing increasingly complex noise pollution challenges, AI-driven noise simulation prediction software and highly sensitive on-site detection devices form a closed-loop governance solution. The software can simulate and predict noise distribution in factories, communities, and even cities with high precision based on building structures, equipment layouts, and other parameters, optimizing noise reduction designs in advance. On-site devices act like "acoustic cameras," locating noise sources in real time and accurately quantifying intensity. AI algorithms further analyze massive data, intelligently recommending optimal noise reduction measures—whether adjusting equipment layout, installing customized soundproof barriers, or optimizing traffic flow—ultimately achieving a complete chain from precise prediction to efficient governance, protecting the comfort and health of the sound environment.

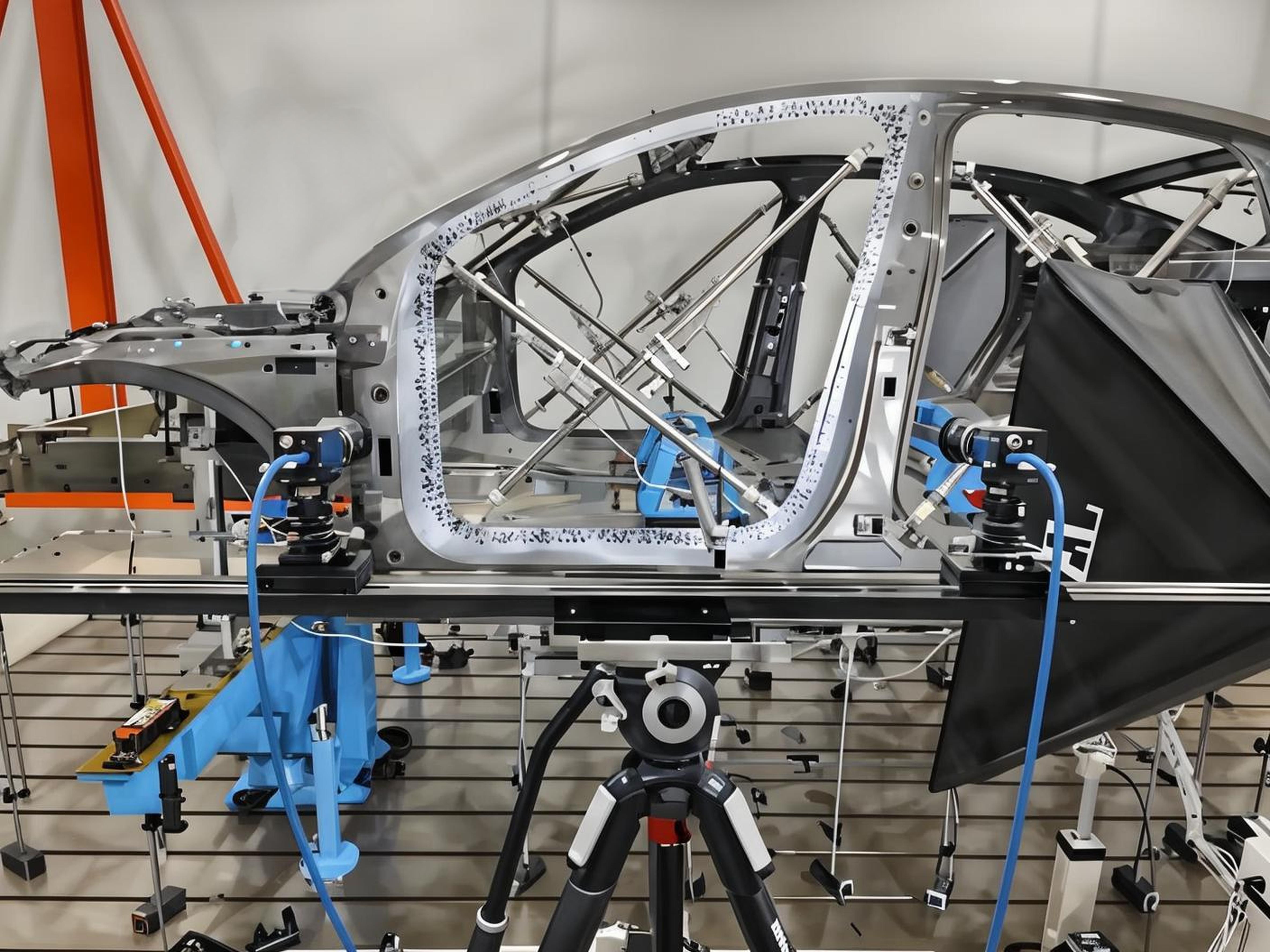

MBD Software + Intelligent Coordinate Measuring Machines: The "Quality Gatekeeper" Throughout the Product Lifecycle

The combination of Model-Based Definition (MBD) technology and intelligent coordinate measuring equipment is enabling full-process quality control from "digital twin" to physical entity. During the design phase, MBD software embeds precise 3D annotations (dimensions, tolerances, process requirements) directly in the CAD environment, becoming the sole authoritative data source. In manufacturing and inspection stages, intelligent coordinate measuring machines directly read MBD model information, automatically plan measurement paths, efficiently complete high-precision inspections, and provide real-time feedback to the system. AI algorithms deeply compare design models with actual measurement data streams to achieve trend prediction, anomaly warning, and process optimization. This combination ensures that product quality is always known, controllable, and traceable throughout the entire lifecycle from design, manufacturing, service, to disposal and recycling.

HALT System + DIC + Surface Pressure Sensors: The "Reliability Forge" Under Extreme Conditions

The integration of Highly Accelerated Life Test (HALT) systems with Digital Image Correlation (DIC) measurement technology and dynamic surface pressure measurement systems establishes a rigorous "testing ground" for product reliability. The HALT system rapidly triggers potential defects under extreme stresses far beyond normal specifications (severe temperature changes, multi-axis vibrations, shocks, etc.). Meanwhile, the DIC system non-contactly measures minute surface deformations and strain distributions of test specimens; high-dynamic surface pressure sensors capture pressure fluctuations at critical contact points in real time. AI algorithms synchronously analyze these three massive data streams to accurately locate failure points, trace failure mechanisms, and intelligently recommend design or material improvement plans. This combination greatly shortens reliability verification cycles and significantly enhances product durability under harsh environments.

"The deep integration of artificial intelligence and core PHM technologies marks a new intelligent stage for predictive maintenance and health management," commented Professor Zhang Ming, a domestic expert in intelligent manufacturing. "This not only greatly improves the safety and efficiency of equipment operation but also profoundly changes how we understand human health, manage environmental quality, and ensure industrial product reliability. In the future, with data fusion and algorithm optimization, its application scenarios will explode in growth."

According to industry analysis agencies, the global PHM market will continue to grow rapidly under AI-driven momentum, with its core value shifting from "post-failure repair" to "precise pre-failure intervention." The outstanding performance of artificial intelligence in the PHM field is building a critical intelligent barrier connecting individual health, livable environments, and industrial safety, profoundly shaping the new landscape of future industries and life.

PHM Industry,Artificial Intelligence,Health Monitoring,Product Reliability,Surface Pressure Measurement,Intelligent Monitoring Technology

Previous Page

Previous Page