|

|

|

Manufacturer Introduction:

The highly accelerated life test system represented by Beijing Qiaozhe Technology Co., Ltd. is manufactured by the American company HANSE.

HANSE is a major global supplier of HALT & HASS, ESS, special environmental test chambers, standalone environmental test chambers, and six degrees of freedom vibration systems, with over 20 years of R&D and practical experience. HANSE has now launched a 100Grms vibration system, placing it once again at the forefront of all competitors.

Product Description:

Highly Accelerated Life Test (HALT)

HALT testing is used in the design and development stage of products, applying gradually increasing environmental stress to identify the product's usage limits and failure limits, exposing various inherent defects and weaknesses of the product. Design and development personnel analyze and improve the defects and weaknesses revealed in the HALT test to enhance product reliability and lifespan..

Highly Accelerated Stress Screening (HASS)

Function Description:

HALT has nine benefits:

♦ Quickly identify product process defects (identify defects quickly within 3-5 days)

♦ Growth in the manufacturing process, accelerating design and manufacturing maturity (after failure due to stimulation, modify the design to accelerate design and manufacturing maturity);

♦ Shorten time to market, accelerate product launch (shorten testing time);

♦ Improve MTBF (Mean Time Between Failures);

♦ Extend warranty period;

♦ Reduce warranty costs (reduce recall and repair costs);

♦ Early availability of product strength data (means to improve product strength);

♦ Reduce costs (shorten product development time and costs);

♦ Customers use highly reliable products

(Resolve design flaws before market launch, improve customer satisfaction, enhance the company's good quality image, and increase market share).

HALT technology aims to increase reliability in the shortest time and with the least cost, to produce world-class quality products,establishing environmental stress screening HASS levels for mass production processes.

System Characteristics:

Temperature:

- Temperature range: -100°C - +200°C

- Temperature change rate can reach 70°C/min

- Temperature control stability reaches ±1°C

- Cooling: uses liquid nitrogen direct spray cooling, equipped with InfitrolTM proportional control valve and safety valve

- Heating: 3 groups of heating wires are evenly controlled, open nickel-chromium electric heating wire heating system

Vibration:

- 3-axis 6 degrees of freedom (6DoF) vibration

- Vibration frequency range 5-10000Hz, 90% of vibration energy distributed in 5-4000Hz

- Vibration intensity can reach up to 100Grms (empty platform)

- Special ceramic coated vibration table

- Air hammer and vibration table provide a three-year unconditional commercial warranty

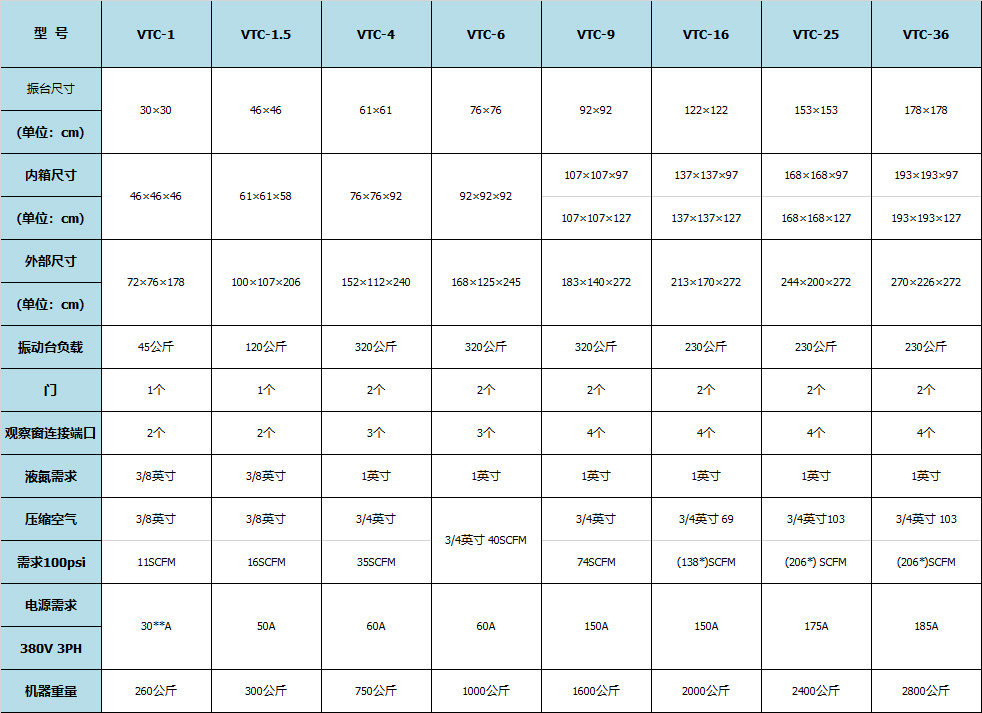

Specification Description:

Application Fields:

The HALT/HASS system designed by HANSE has over 20 years of R&D and practical experience and is recognized as one of the fastest and most effective methods for reliability testing of electronic, electromechanical, and other products,

capable of quickly revealing product defects, reducing R&D, design, and repair costs; improving product reliability,

Shorten time to market. Widely used in fields such as electronics, communications, automotive, aerospace, aviation, military, medical equipment, and energy equipment.

Application cases:

Application images:

Customer base:

Domestic and international customers, including the 3C industry, automotive industry, and research centers.